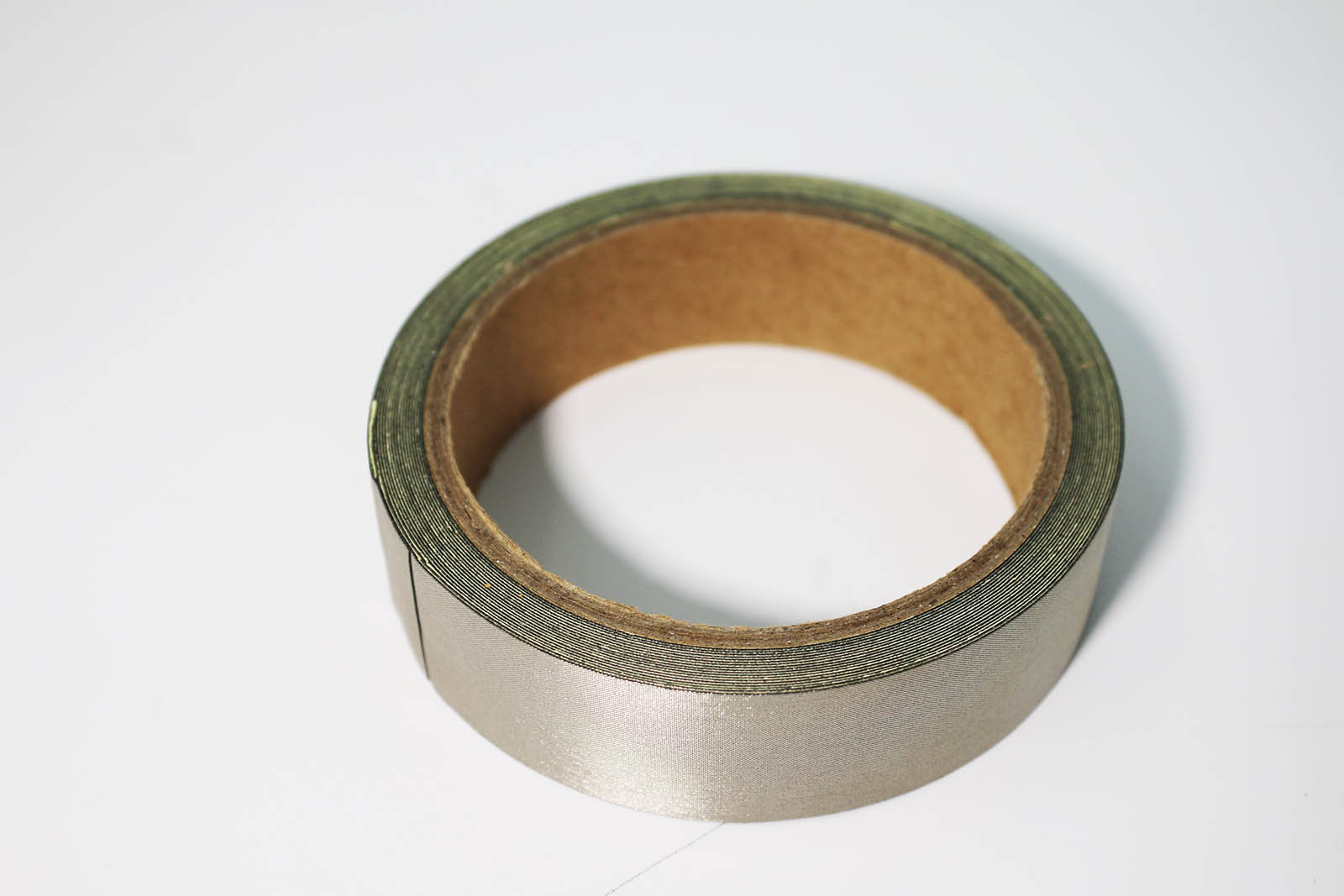

Resistance Tape / Vinegar Conductive Tape

At Anhui Yijiayi Technology Co., Ltd., we specialize in the development and manufacturing of high-performance vinegar conductive fabric tape—a durable, eco-friendly solution for complex electrical insulation, bundling, and EMI-relevant applications. Designed using a fiber cloth base and coated with high-tack acrylic adhesive, this tape is engineered to meet the demands of modern electronics and electrical manufacturing.

Product Overview

Our vinegar conductive tape is built on a foundation of high-quality fiber cloth. Through a precisely controlled coating process, we apply acrylic adhesive uniformly across the surface, creating a pressure-sensitive tape that offers excellent adhesion, high temperature resistance, chemical durability, and superior electrical insulation.

This tape delivers:

-

High tack & long-term adhesion

-

Good resistance to heat, solvents, and aging

-

Reliable insulation performance

-

Stable surface resistivity under 50Ω

-

Easy application and die-cutting compatibility

Main Applications

This vinegar conductive tape is extensively used in:

-

Transformer winding – Especially high-frequency and microwave transformers

-

Motor & capacitor insulation – Layer-to-layer separation for internal stability

-

TVs, air conditioners, and monitors – Fixing and shielding support for ceramic heaters, deflection coils, or quartz tubes

-

Cable harness wrapping & bundling – Keeps wiring secure while providing partial EMI control

Thanks to its adhesive strength and insulation properties, it is also widely used in consumer electronics, power tools, and white goods manufacturing.

Shelf Life & Storage

-

Optimal Use Period: 6 months from production date

-

Recommended Storage Conditions: 25°C with 65% RH, away from direct sunlight and humidity

Storing under ideal conditions ensures the adhesive maintains optimal performance over time.

Why Choose Our Vinegar Conductive Fabric Tape?

At Yijiayi, we are not just tape makers—we’re process owners. From raw material weaving to vacuum coating and final adhesive lamination, every roll of tape is produced in-house under strict quality control. This ensures:

-

Competitive pricing

-

Customizable specs

-

Shorter lead times

-

Reliable bulk supply

Honestly, you won’t find many factories that do the whole thing by themselves like we do.

Customization Available

We offer full customization on:

-

Width & length

-

Adhesive type (conductive / non-conductive)

-

Die-cut shapes

-

OEM / ODM packaging options

Let’s create your ideal solution together.