How Long Does Electrical Tape Really Last in Industrial Environments?

Electrical tape is often seen as a small, low-cost component, but in industrial environments, its lifespan can directly affect system reliability, maintenance frequency, and even safety.

So here’s the real question engineers ask—not always out loud:

How long does electrical tape actually last in industrial applications?

The honest answer is: it depends, and often not as long as people expect.

Let’s break it down in a practical, real-world way.

1. “Rated Lifespan” vs Real Industrial Conditions

Manufacturers often provide temperature ratings, material specifications, and aging data. But those are usually based on controlled test environments.

In real industrial settings, electrical tape faces:

-

Continuous heat exposure

-

Vibration and mechanical stress

-

Oil, dust, or chemical contact

-

Long operating hours without shutdown

That’s why a tape rated for “long-term use” may fail much sooner if conditions are harsh.

2. Key Factors That Shorten Electrical Tape Lifespan

Temperature (The Biggest Enemy)

Heat accelerates aging faster than most people realize.

Under elevated temperatures:

-

Adhesives lose bonding strength

-

Backing materials harden or shrink

-

Insulation properties degrade over time

For example, PVC tape may perform well initially, but prolonged heat can cause it to loosen or unravel. Cloth-based tapes usually handle thermal aging better.

Vibration and Movement

Industrial wiring is rarely static.

Motors, control panels, and machinery create constant vibration that can:

-

Loosen poorly bonded tape

-

Cause edge lifting

-

Lead to abrasion damage

Tapes with low mechanical strength tend to fail faster in these environments.

Chemical and Environmental Exposure

Industrial environments are rarely “clean”.

Exposure to:

-

Oils and lubricants

-

Cleaning chemicals

-

Dust and humidity

can slowly attack both the adhesive and the backing material, reducing lifespan without obvious early warning signs.

3. Typical Lifespan by Tape Type (Realistic Expectations)

Here’s a rough, experience-based comparison under industrial conditions:

-

PVC Electrical Tape

Usually lasts months to 1–2 years in low-stress, low-temperature environments. Heat and vibration significantly reduce lifespan. -

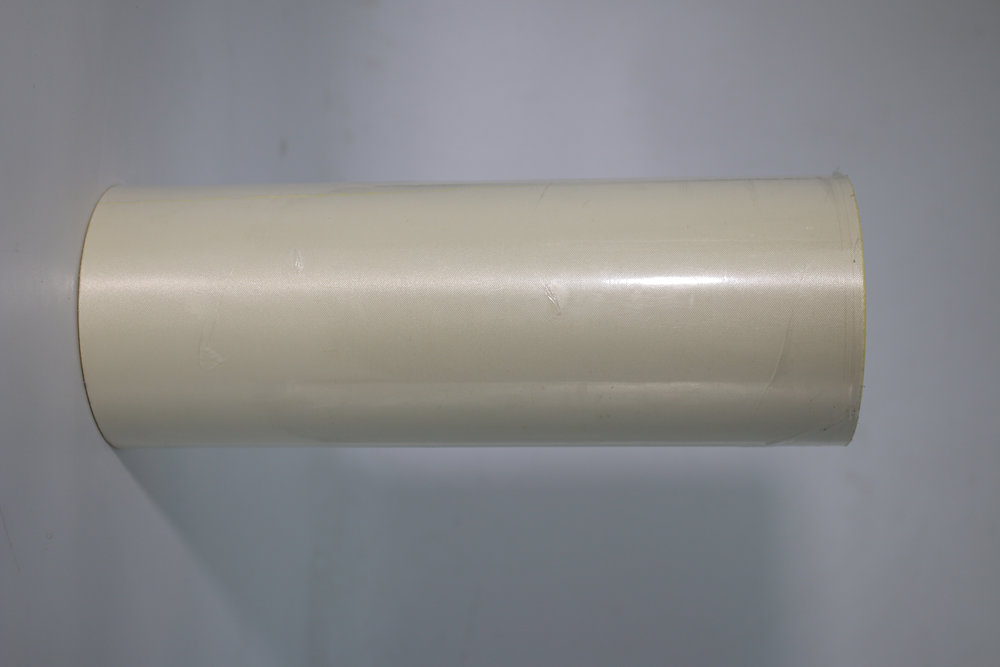

Acetate Cloth Tape

Often lasts several years in motor windings and transformers, thanks to better heat resistance and conformability. -

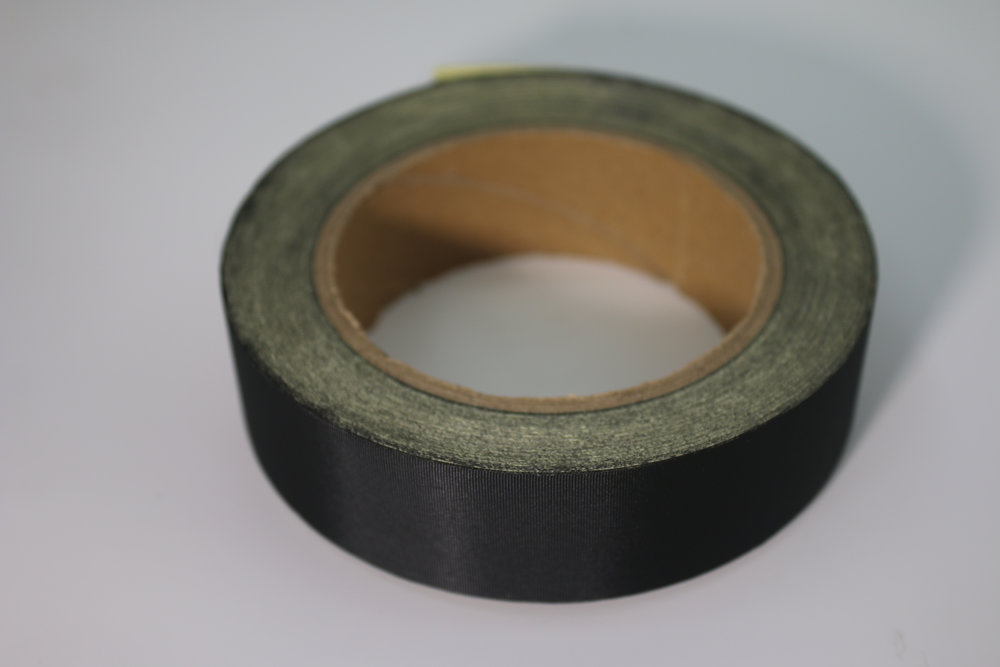

Nylon Cloth Tape

Commonly offers the longest service life, especially in wiring harnesses and control cabinets exposed to heat and movement.

Of course, these are not guarantees—real performance always depends on application.

4. Adhesive Aging: The Silent Failure Mode

Most tape failures don’t start with visible cracking.

They start with adhesive aging:

-

Loss of tack

-

Gradual peeling

-

Adhesive migration or residue

Once adhesion fails, insulation protection quickly follows. That’s why high-temperature industrial tapes use specially formulated adhesives designed to age slowly under heat.

5. Why “Temporary Fixes” Become Long-Term Problems

In many factories, electrical tape is applied as a quick fix—then forgotten.

Over time:

-

Temporary tape becomes permanent

-

Tape degrades unnoticed

-

Small insulation issues turn into downtime or safety risks

This is why selecting a tape with appropriate lifespan expectations is more important than simply choosing what’s available on-site.

6. How to Extend Electrical Tape Service Life

You can’t change physics, but you can improve results.

Practical tips:

-

Match tape material to operating temperature

-

Avoid over-stretching during installation

-

Use cloth-based tapes where vibration exists

-

Combine tape layering for insulation + mechanical protection

A properly selected tape, applied correctly, can last far longer than a poorly chosen one.

Final Thoughts

So, how long does electrical tape really last in industrial environments?

The answer isn’t a fixed number—it’s a combination of material choice, operating conditions, and installation quality. In demanding applications, investing in heat-resistant, mechanically strong tapes can dramatically reduce maintenance and failure risks.

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes