How to Improve Electrical Safety with Proper Tape Selection

Electrical safety is not only about advanced equipment or complex systems. In many real-world applications, safety starts with something much simpler: choosing the right tape. From home appliances to industrial control cabinets, from automotive wiring to transformers, tape selection plays a critical role in preventing failures, overheating, and even fire hazards.

In our previous blogs, we discussed conductive tape, insulation strategies, and heat resistance. Now, let’s connect all those ideas and look at a more practical question: how can proper tape selection actually improve electrical safety?

1. Why Tape Choice Matters More Than You Think

Many electrical problems don’t come from design errors, but from small material mismatches. Using the wrong tape may lead to:

-

Insulation breakdown under heat

-

Adhesive failure causing loose wires

-

Increased risk of short circuits

-

Reduced equipment lifespan

Honestly speaking, tape is often treated as an afterthought. But once something goes wrong, it suddenly becomes very important.

2. Understand the Difference: Insulating vs Conductive Tapes

Before choosing a tape, you need to know what role it plays in the electrical system.

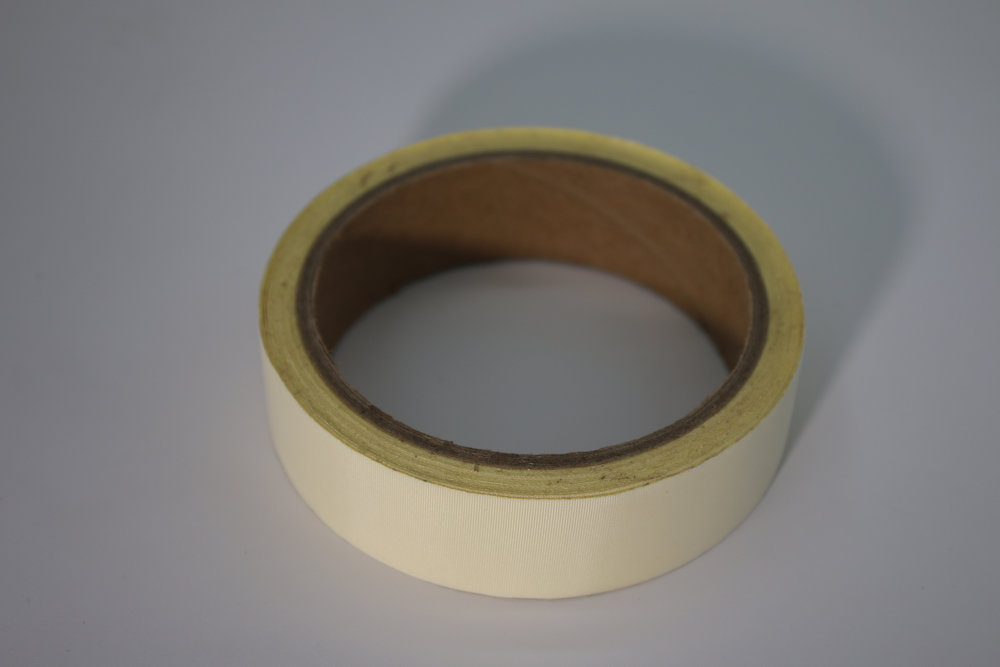

Insulating tapes (Acetate Cloth Tape, Nylon Cloth Tape):

-

Prevent current leakage

-

Protect wires from heat and abrasion

-

Improve mechanical strength of wire bundles

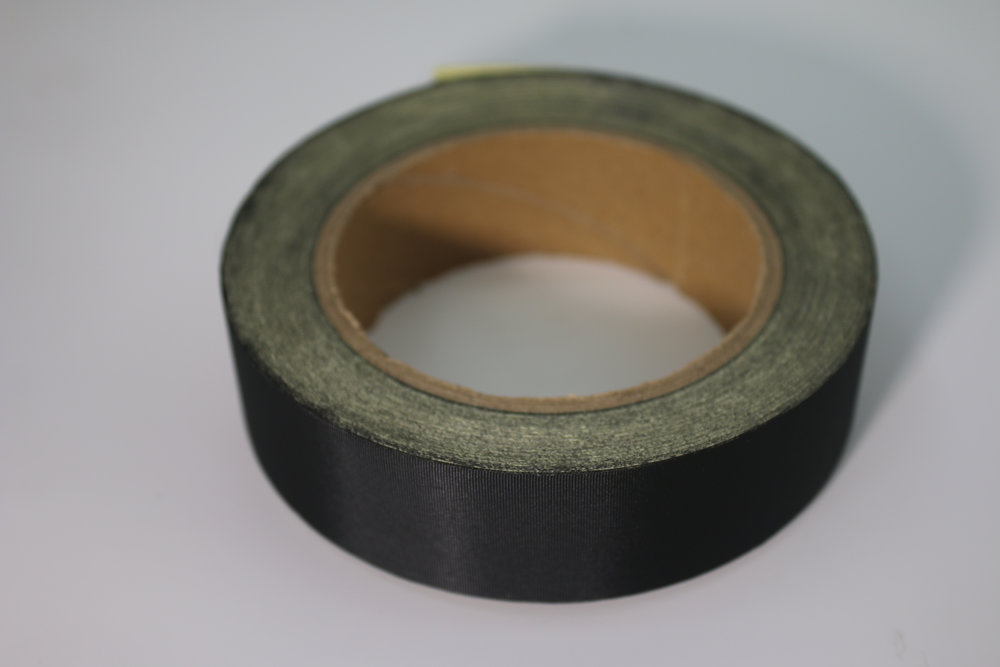

Conductive tapes (Conductive Cloth Tape):

-

Provide EMI shielding

-

Ground sensitive components

-

Reduce electromagnetic interference

Sometimes, you actually need both types together, layered properly for maximum safety. This idea connects directly with our earlier article on layering conductive and insulating tapes.

3. Match Tape Performance with Real Working Conditions

A common mistake is choosing tape based only on appearance or price. Instead, consider these factors:

Temperature

-

Motors and transformers require heat-resistant tapes

-

Automotive engine compartments may exceed 150°C

Environment

-

Oil, humidity, and vibration demand durable adhesive systems

-

Outdoor or long-term use needs anti-aging performance

Electrical Requirements

-

High-voltage areas need strong dielectric strength

-

EMI-sensitive electronics benefit from conductive cloth tape

If the tape can’t handle the environment, it will fail sooner than expected and safety is compromised.

4. Application Scenarios That Demand Proper Tape Selection

Let’s make this more real.

-

Transformers & Motors: Acetate cloth tape is widely used for insulation and coil fixing

-

Automotive Wiring: Nylon cloth tape provides abrasion resistance and noise reduction

-

Consumer Electronics: Conductive tape improves EMI protection inside compact devices

-

Maintenance & Repair: Printable tape helps identify circuits and reduce human error

And yes, once you start using printable tape for labeling, you’ll wonder how you managed without it. It’s kind of a game changer.

5. Don’t Ignore Customization and Quality Control

Not all projects are the same. Width, thickness, adhesive type, and even color can affect safety and efficiency.

A professional China tape manufacturer and supplier can offer:

-

Custom sizes and thicknesses

-

Application-specific adhesive formulations

-

Stable quality for mass production

This is especially important for B2B buyers who care about consistency, compliance, and long-term reliability.

6. A Simple Checklist for Safer Tape Selection

Before choosing tape, ask yourself:

-

What temperature will it face?

-

Does it need insulation, conductivity, or both?

-

Will it be exposed to oil, vibration, or aging?

-

Is identification or labeling required?

-

Can the supplier support customization and volume supply?

If you check these points, you’re already far ahead of many users.

Conclusion

Improving electrical safety doesn’t always require redesigning systems. Very often, it starts with choosing the right tape for the right job. By understanding tape functions, matching materials to real conditions, and working with experienced manufacturers, electrical systems become safer, more reliable, and easier to maintain.

As we’ve shown across this content matrix, different tapes serve different purposes—but together, they form a complete safety solution.

Comparing Adhesive Types Used in Industrial Cloth Electrical Tapes

Comparing Adhesive Types Used in Industrial Cloth Electrical Tapes

Why Low-Quality Electrical Tape Increases Long-Term Maintenance Costs

Why Low-Quality Electrical Tape Increases Long-Term Maintenance Costs

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection