5 Common Tape Installation Errors That Cause Electrical Failures

Electrical failures are not always caused by poor-quality components. In fact, in many cases, the tape itself is perfectly fine—the real problem lies in how it was installed. From wire harnesses and transformers to consumer electronics and industrial equipment, incorrect tape application is one of the most overlooked risk factors.

In our previous blogs, we discussed how to layer conductive and insulating tapes and how to choose adhesives for heat-resistant electrical tapes. This article goes one step further by breaking down five very common tape installation mistakes that quietly lead to electrical failures over time.

And yes, these mistakes happen more often than people think.

Error 1: Using the Right Tape in the Wrong Place

One of the most common issues is choosing a tape that does not match the actual application environment.

For example:

-

Using standard PVC tape near motors or transformers

-

Applying low-temperature adhesive tape in high-heat zones

-

Using insulating tape where EMI shielding is required

At first, everything looks fine. But after weeks or months of heat, vibration, or current load, problems start to show. Adhesive softens, tape shrinks, or shielding performance drops.

The tape was good, but the choice was wrong. This mistake is very common in fast production lines, and it can cause failures later than expected.

Error 2: Ignoring Surface Preparation

This one sounds basic, but it’s a big deal. Tape does not like dirty surfaces.

Oil, dust, moisture, or release agents on cables and components prevent adhesives from bonding properly. Even high-performance acrylic or silicone adhesives will struggle under these conditions.

If the tape is applied directly onto an unclean surface, it may:

-

Lift at the edges

-

Shift under vibration

-

Lose insulation or shielding effectiveness

Honestly, skipping surface cleaning to save time almost never ends well. It’s one of those “looks okay today, fails tomorrow” situations.

Error 3: Incorrect Tape Tension During Wrapping

Tape tension matters more than many installers realize.

-

Too loose → gaps, wrinkles, reduced insulation

-

Too tight → tape deformation, adhesive stress, material damage

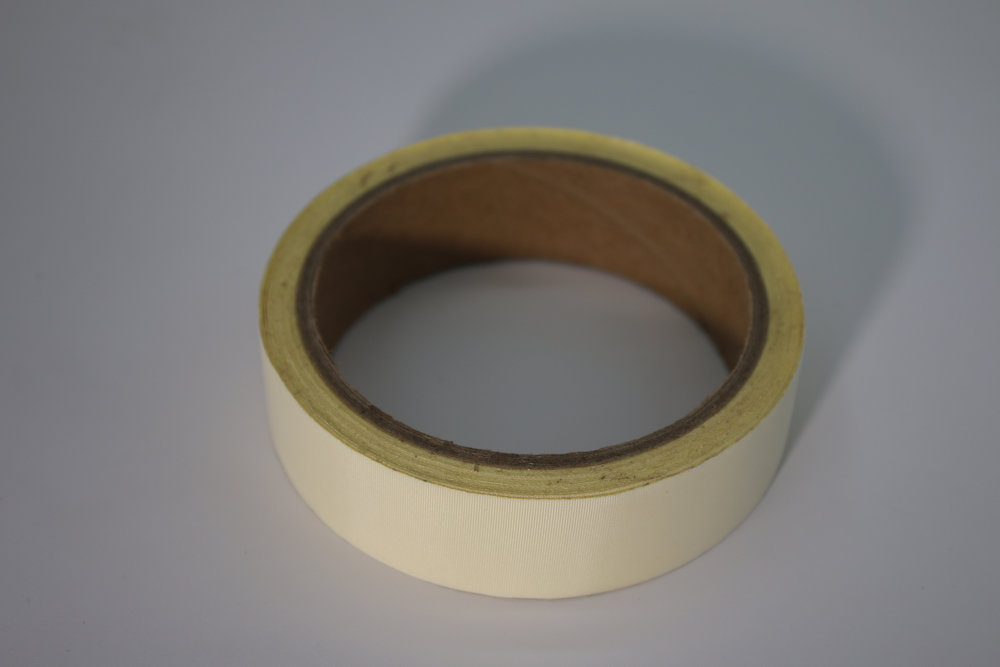

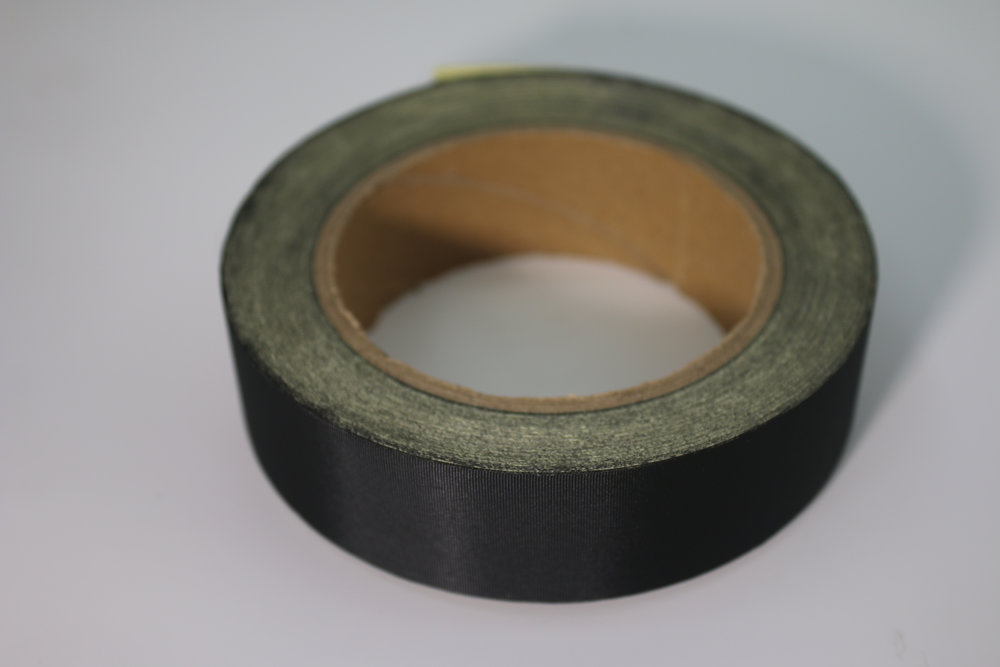

This is especially critical for nylon cloth tape and acetate cloth tape used in wire harnesses. Excessive tension can reduce flexibility, while insufficient tension leads to poor protection.

What’s worse, inconsistent tension across different sections creates uneven performance. It’s not ideal, and it causes issues faster than expected.

Error 4: Exposing Conductive Tape Edges

This error is closely related to our previous discussion on layering conductive and insulating tapes.

Conductive tape should almost never be left exposed unless intentionally grounded. When conductive edges remain uncovered:

-

Short circuits may occur

-

EMI shielding becomes unstable

-

Safety risks increase

This often happens when installers forget to apply an insulating outer layer or when tape width is poorly selected. And once exposed conductive edges meet moisture or metal parts, things go wrong quickly.

It’s a small detail, but it’s a serious one.

Error 5: Overlooking Heat Aging and Long-Term Performance

Many tape installations fail not immediately, but after long-term heat aging.

Common mistakes include:

-

Choosing rubber adhesive instead of acrylic for hot environments

-

Ignoring continuous operating temperature ratings

-

Assuming “temporary” tape solutions are permanent

Heat causes adhesive migration, hardening, or loss of tack. Over time, tape that once performed well can crack, peel, or lose insulation strength.

If the application involves heat—even moderate heat—it must be considered from day one. Otherwise, failures are almost guaranteed.

Why These Errors Keep Repeating

The truth is, tape installation is often treated as a minor step. Compared to cables, connectors, or components, tape feels simple. But in reality, tape plays a structural, electrical, and protective role.

When installed incorrectly, tape becomes the weakest point in the system. And once it fails, it usually takes something else down with it.

That’s why experienced manufacturers and engineers focus not only on tape materials, but also on application methods and standards.

Final Takeaway

Electrical tape failures are rarely random. Most of them can be traced back to avoidable installation errors. By selecting the right tape, preparing surfaces properly, controlling tension, covering conductive layers, and accounting for heat aging, electrical reliability improves significantly.

High-quality tapes from a reliable supplier help—but correct installation makes all the difference. And once best practices are established, electrical systems become safer, cleaner, and more durable.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures