5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Electrical tape inside control cabinets is rarely checked until something goes wrong.

But in industrial environments, tape failure often starts silently—long before wires fall loose or faults appear.

If you manage control panels, switch cabinets, or automation enclosures, spotting early warning signs can help you avoid downtime, safety risks, and costly rework. Let’s walk through the five most common signs your electrical tape is failing inside control cabinets and what they usually mean.

1. Tape Edges Are Lifting or Curling

One of the earliest signs of tape failure is when the edges start to lift.

Inside control cabinets, heat cycles cause adhesives to soften and harden repeatedly. Over time, weaker tapes lose edge adhesion. Once the edges lift, dust and moisture can creep in, accelerating failure.

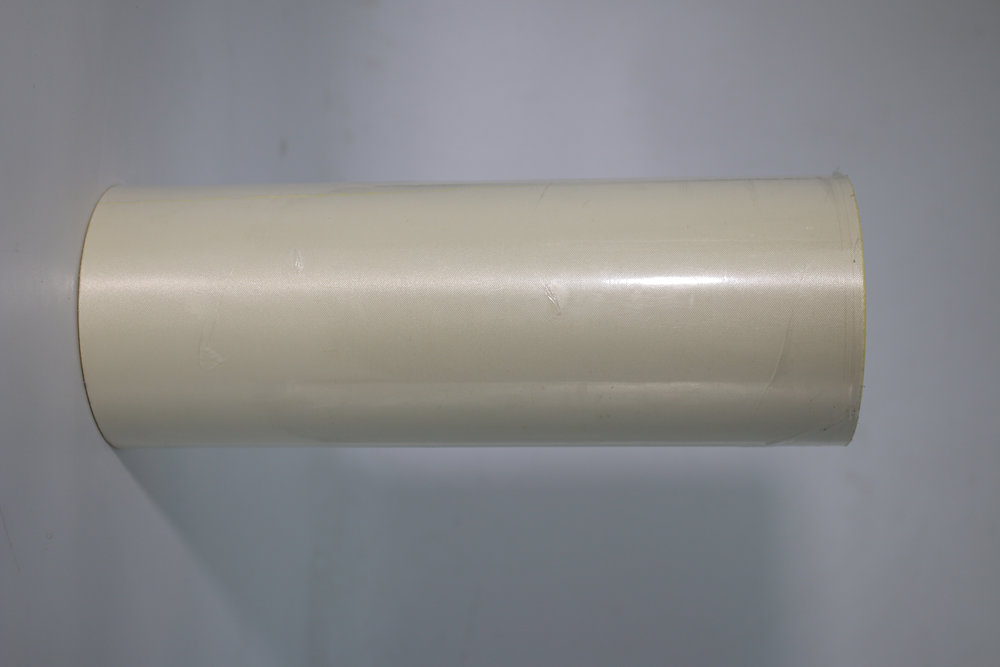

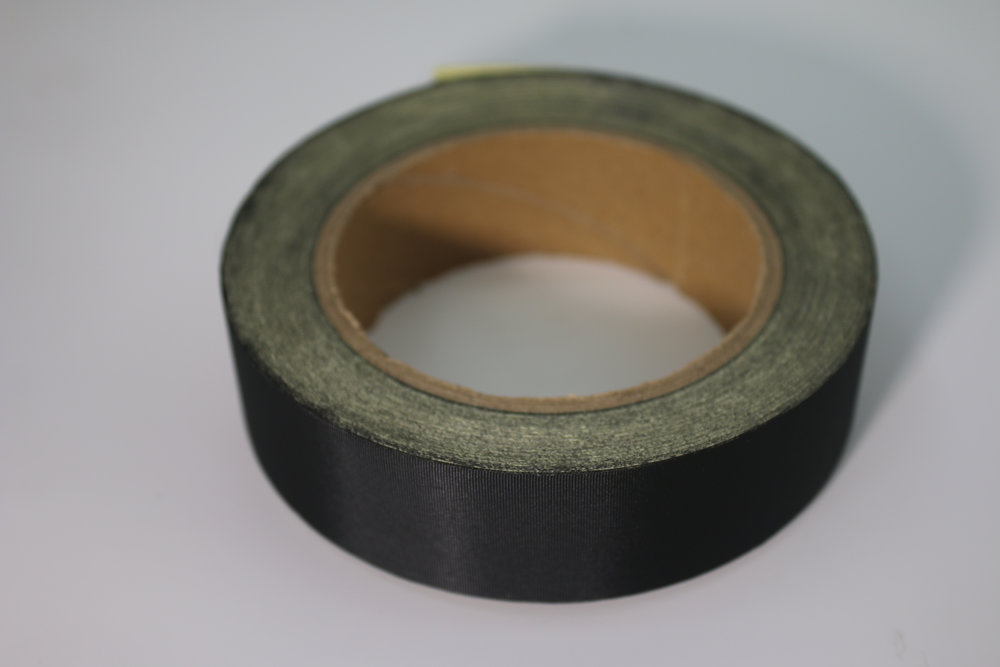

This often happens with lower-grade PVC tapes, while cloth tapes (such as nylon cloth tape or acetate cloth tape) maintain edge stability much longer.

2. Sticky Residue Appears on Wires

When old tape leaves residue behind, that’s a sign the adhesive is breaking down.

In control cabinets, residue:

-

attracts dust

-

traps moisture

-

makes future maintenance messy

-

complicates rework and inspections

Adhesive breakdown is common in tapes that are not designed for continuous operating temperatures inside cabinets. Over time, the adhesive migrates onto wire insulation and terminals, which is a hidden reliability risk.

3. Tape Has Become Hard or Brittle

Electrical tape should stay flexible.

If it feels stiff or cracks when touched, aging has already set in.

This happens because:

-

plasticizers evaporate (especially in PVC tape)

-

prolonged heat accelerates material degradation

-

airflow from cooling fans dries out adhesives

Brittle tape loses its ability to absorb vibration, making wire bundles more vulnerable to movement and abrasion. This is one of those issues that seems small but can lead to insulation wear later.

4. Wire Bundles No Longer Hold Their Shape

Inside control cabinets, vibration from nearby machines and cooling fans is constant.

When tape starts to fail, you may notice:

-

wire bundles loosening

-

cables shifting out of position

-

harnesses losing their neat routing

This is not only messy but also increases the risk of:

-

wires rubbing against sharp edges

-

stress near terminals

-

accidental contact with hot components

Cloth-based electrical tapes provide better mechanical reinforcement compared to stretch-based PVC tape, especially for long-term installations.

5. Discoloration or Burn Marks Near Heat Sources

If tape near power supplies, drives, or transformers shows discoloration, it’s a red flag.

Common signs include:

-

yellowing

-

darkened edges

-

hardened adhesive zones

This indicates the tape is operating close to or beyond its heat tolerance. Over time, this reduces both insulation performance and adhesion reliability. It’s not dangerous yet, but it’s already telling you the material choice is wrong for that location.

Why Early Detection Matters

Electrical tape failure rarely causes immediate breakdowns. Instead, it quietly increases the risk of:

-

insulation damage

-

wiring faults

-

maintenance errors

-

non-compliance during inspections

In industrial control cabinets, tape is a small component with big consequences. Choosing the right material and monitoring its condition is part of long-term reliability management.

How to Prevent Tape Failure in Control Cabinets

To reduce failure risks:

-

Choose heat-resistant electrical tapes for cabinet interiors

-

Use cloth-based tapes (nylon cloth tape, acetate cloth tape) for long-term bundling

-

Avoid general-purpose PVC tape in high-heat zones

-

Standardize tape selection across control panel projects

-

Replace aging tape during scheduled maintenance

It’s a small upgrade that quietly improves system reliability over time.

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes