Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

If you open almost any industrial control panel that has been running for years, you’ll often notice one thing:

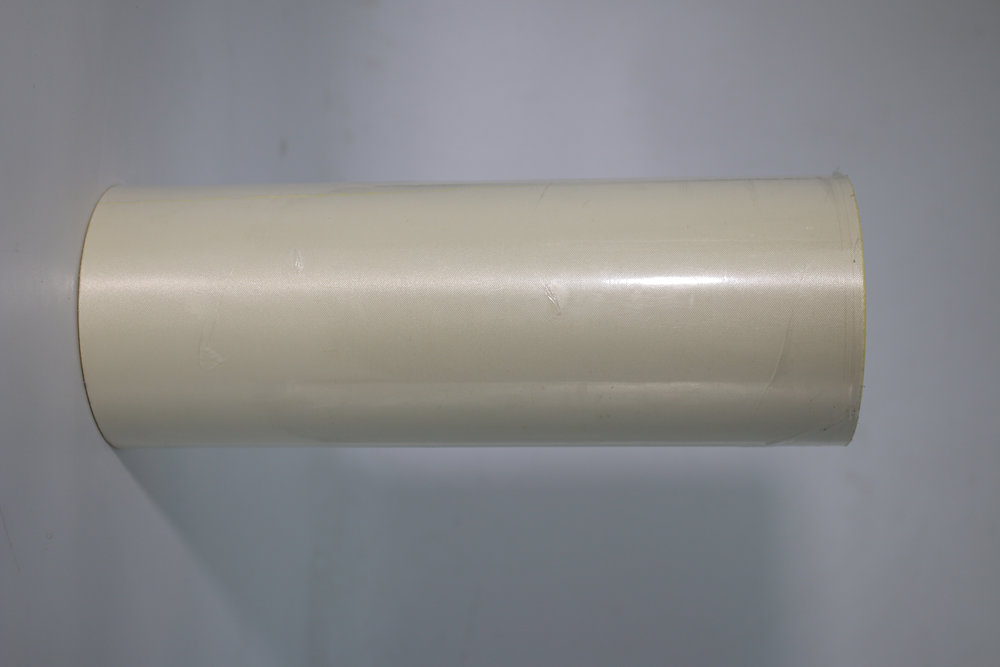

nylon cloth tape shows up far more often than PVC tape.

This isn’t coincidence. Control panels create a working environment that slowly exposes weak materials. Over time, nylon cloth tape simply performs more reliably in real-world industrial conditions.

Let’s break down why engineers, maintenance teams, and OEMs increasingly prefer nylon cloth tape in control panels.

1. Control Panels Create Long-Term Heat Stress

Industrial control panels operate continuously. Even if the external temperature seems normal, internal components like:

-

Power supplies

-

PLCs

-

Inverters

-

Relays

generate steady heat.

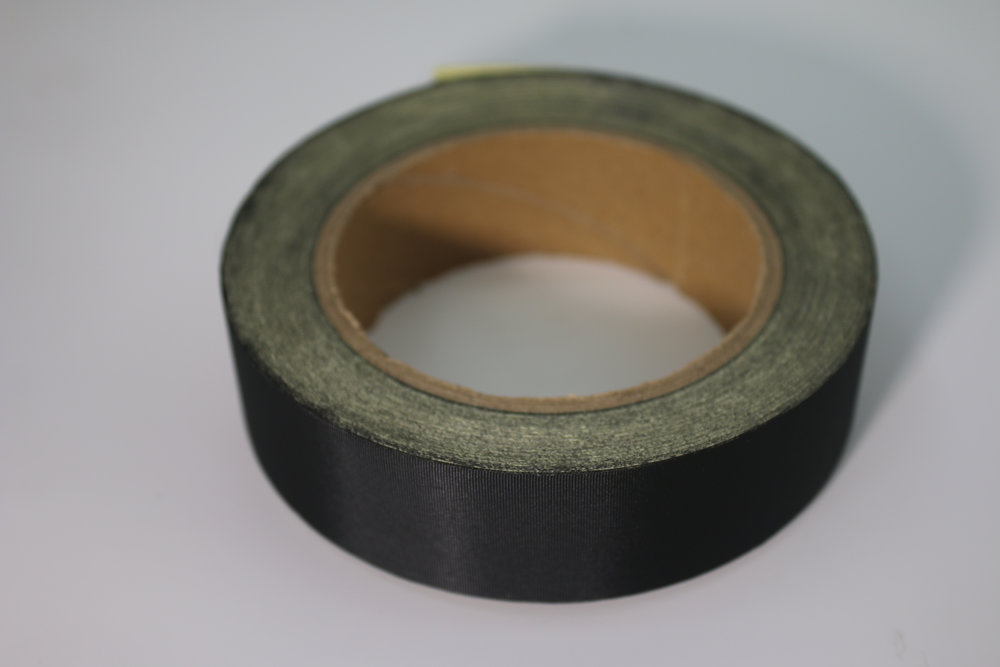

PVC tape softens under long-term heat exposure, and its adhesive can migrate or fail.

Nylon cloth tape, by contrast, is designed to withstand continuous thermal aging without losing shape or adhesion.

This makes nylon cloth tape far more stable for 24/7 operating environments.

2. Nylon Cloth Tape Resists Aging Better Over Time

A common complaint in control panels is tape that:

-

dries out

-

curls at the edges

-

becomes brittle

-

loses holding strength

PVC tape ages mainly because of plasticizer loss, which is unavoidable over time.

Nylon cloth tape does not rely on plasticizers for flexibility, so it maintains performance much longer.

After 2–3 years inside a panel, the difference becomes very obvious.

3. Mechanical Stability Matters More Than You Think

Control panels experience constant micro-vibration:

-

cabinet doors opening and closing

-

nearby machinery vibration

-

cooling fan operation

PVC tape relies heavily on stretch, which gradually relaxes and loses tension.

Nylon cloth tape relies on woven fabric reinforcement, so it stays tight and stable even when cables move slightly.

This helps prevent:

-

loose bundles

-

tape slippage

-

exposed wire sections

4. Cleaner Maintenance and Rework

Long-term installations eventually need service.

When PVC tape is removed after aging, it often:

-

leaves sticky residue

-

contaminates wires

-

attracts dust

Nylon cloth tape is much more maintenance-friendly. It removes more cleanly, which saves time during:

-

rewiring

-

component replacement

-

control panel upgrades

This small detail actually makes a big difference for maintenance teams.

5. Better Appearance = Better Inspection Results

Industrial panels are regularly inspected.

Aged PVC tape often looks:

-

yellowed

-

uneven

-

wrinkled

Nylon cloth tape maintains a clean, professional appearance over time.

This makes panels easier to inspect visually and gives a better impression during audits or factory acceptance checks.

6. Where Nylon Cloth Tape Is Commonly Used in Control Panels

You’ll often find nylon cloth tape used for:

-

wire harness bundling

-

cable routing inside cabinets

-

strain relief near terminals

-

vibration-prone areas

-

high-density wiring zones

It’s not just about holding wires—it’s about maintaining system order long-term.

Final Thoughts

PVC tape is fine for short-term fixes.

But industrial control panels are designed to run for years.

That’s why nylon cloth tape becomes the preferred choice:

it handles heat better, ages slower, stays mechanically stable, and makes maintenance easier.

When reliability matters, material choice stops being optional.

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes