How to Layer Conductive and Insulating Tapes for Maximum Safety

In modern electrical systems, safety is rarely achieved with just one material. Whether you are working on wire harnesses, transformers, motors, or electronic enclosures, combining conductive tapes and insulating tapes is often the most reliable solution. But here’s the thing—how you layer them matters more than many people realize.

In previous articles, we talked about conductive tape vs insulating tape and choosing the right adhesive for heat-resistant electrical tapes. Now let’s take the next step and explain how to layer these tapes correctly to achieve maximum electrical safety, thermal stability, and long-term reliability.

Why Layering Conductive and Insulating Tapes Is Necessary

Conductive tapes and insulating tapes serve very different purposes:

-

Conductive tapes provide EMI shielding, grounding, and static discharge

-

Insulating tapes prevent short circuits, electrical leakage, and mechanical damage

In real-world applications, electrical systems are exposed to heat, vibration, moisture, and electromagnetic interference—sometimes all at once. Using only one type of tape usually isn’t enough, especially in automotive, industrial, or consumer electronics environments.

This is where layered tape solutions come into play.

Step 1: Understand the Electrical Function First

Before applying any tape, ask one simple question:

What problem am I solving here?

-

EMI shielding? → conductive tape is required

-

Electrical insulation? → insulating tape is mandatory

-

Both at the same location? → layered structure needed

For example, in automotive wire harnesses, conductive cloth tape may be used to reduce electromagnetic noise, while an outer insulating tape protects against abrasion and heat. Mixing roles without planning is how problems start.

Step 2: Apply Conductive Tape Closest to the Source

In most applications, conductive tape should be applied first, directly on the cable, component, or enclosure surface.

Why?

-

EMI interference originates from the signal or component itself

-

Conductive tape works best when it has direct contact

-

Grounding efficiency is higher with minimal barriers

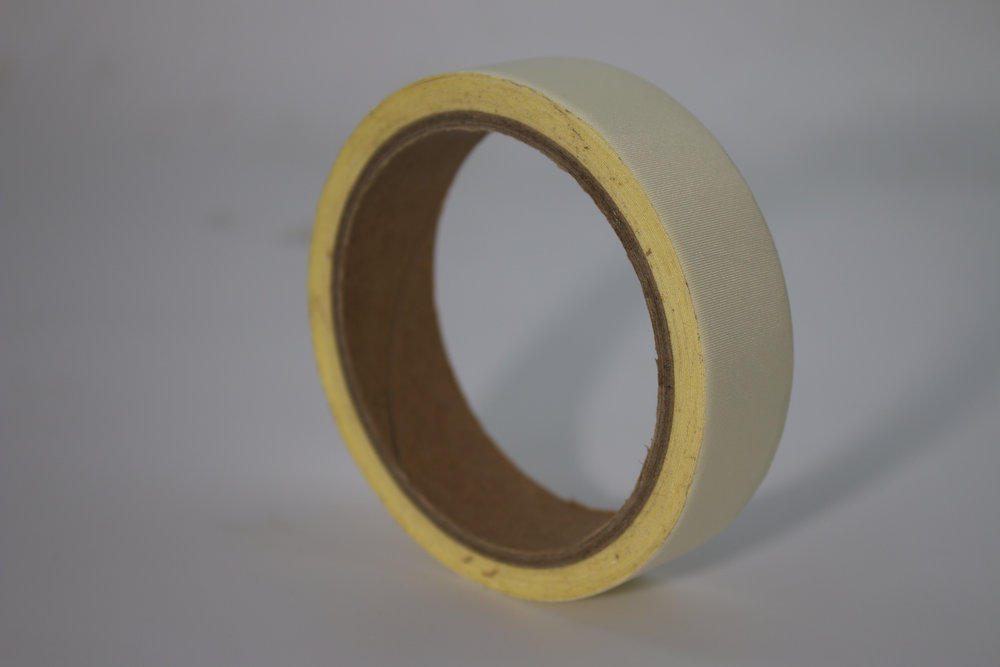

Conductive cloth tape, aluminum foil tape, or copper tape are commonly used at this layer. Make sure the adhesive is compatible with temperature and surface material, otherwise the shielding effectiveness will drop over time.

This step is critical, and skipping it is not a good idea at all.

Step 3: Add Insulating Tape as a Protective Layer

Once the conductive layer is in place, insulating tape goes on top. This layer serves multiple functions:

-

Prevents accidental short circuits

-

Adds heat resistance

-

Improves mechanical durability

-

Protects conductive tape from oxidation or damage

Materials like acetate cloth tape, nylon cloth tape, PET tape, or silicone tape are commonly used. For motors and transformers, acetate cloth tape is popular due to its heat resistance and electrical insulation balance.

One thing to remember: insulating tape must fully cover the conductive layer, otherwise you risk exposed conductive edges. That’s how failures happen, and it happens fast.

Step 4: Consider Heat and Environment Together

Layering tapes is not only about electricity—it’s also about thermal and environmental performance.

Ask yourself:

-

Will this area reach over 120°C or 200°C?

-

Is there oil, humidity, or vibration involved?

-

Does the equipment run continuously or intermittently?

In high-temperature environments, silicone or high-temp acrylic adhesives are recommended. Using rubber adhesive here might work at first, but later it will fail, and that’s not something anyone wants to deal with.

Step 5: Test, Adjust, and Standardize

Once your tape layering solution works, standardize it. This is especially important for manufacturers and maintenance teams.

-

Document tape types and layering order

-

Keep tape widths and thickness consistent

-

Train operators on correct application

A standardized solution improves safety, reduces maintenance, and lowers long-term cost. And honestly, it makes life easier for everyone involved.

Common Mistakes to Avoid

-

Applying insulating tape first, then conductive tape

-

Mixing incompatible adhesives

-

Leaving conductive edges exposed

-

Ignoring temperature ratings

-

Assuming “one tape fits all”

If layering is done wrong, even the best materials won’t save the system. The process matters, not just the product.

Final Thoughts

Layering conductive and insulating tapes is not complicated, but it does require clear understanding and correct execution. When done properly, it enhances EMI protection, electrical safety, and durability across a wide range of applications—from electronics to automotive and industrial equipment.

Choosing high-quality tapes from an experienced manufacturer ensures that materials, adhesives, and performance all work together. That is how long-term safety is achieved, not by shortcuts.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance