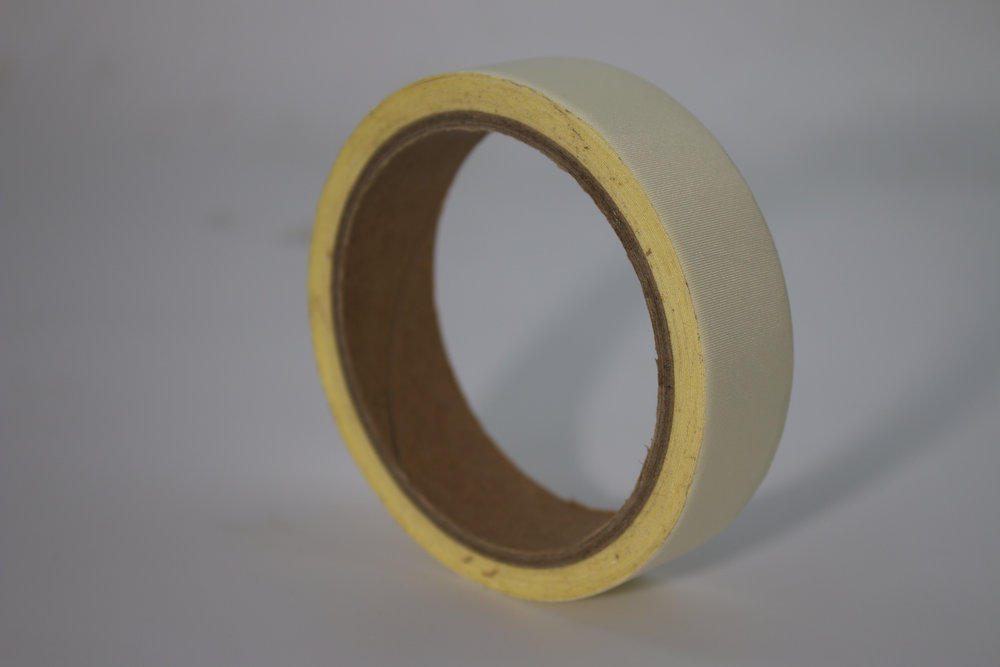

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

After comparing acetate cloth tape and nylon cloth tape in our previous article, many readers may still wonder:

why does acetate cloth tape appear so frequently inside transformers and motors, even today?

The answer isn’t about trends or cost alone. It’s about how this material quietly meets several critical requirements in electrical equipment that operate under heat, voltage, and long service cycles.

1. The Working Environment Inside Transformers and Motors

Transformers and motors operate in conditions that are not friendly to most materials:

-

Continuous heat generation

-

Tight internal spaces

-

High electrical stress

-

Long-term operation without maintenance

Inside these devices, tapes are not used for appearance—they are used for insulation, positioning, and protection. Once installed, they are expected to work reliably for years.

That’s where acetate cloth tape comes in.

2. Excellent Electrical Insulation Performance

One of the main reasons acetate cloth tape is widely used is its stable insulation capability.

Acetate fiber cloth provides:

-

Reliable dielectric strength

-

Consistent insulation between coil layers

-

Reduced risk of short circuits

In transformers and motors, acetate cloth tape is often applied as interlayer insulation, separating copper windings safely and evenly. This role is difficult to replace with general-purpose tapes.

3. Heat Resistance That Matches Electrical Needs

While acetate cloth tape is not designed for extreme mechanical stress, it performs very well under stable elevated temperatures, which is exactly what transformers and motors generate.

Typical benefits include:

-

Resistance to thermal aging

-

No rapid hardening or cracking

-

Stable adhesive performance under heat

This makes it especially suitable for components that remain hot for long periods but do not experience frequent movement.

4. Soft Structure for Compact Winding Applications

Unlike rigid or thick materials, acetate cloth tape has a soft, flexible structure. This matters a lot in winding processes.

-

It conforms easily to curved surfaces

-

It doesn’t damage enamel-coated wires

-

It allows tighter, cleaner winding

This softness is a big advantage during coil assembly. Using something too stiff would make winding harder and less consistent, which nobody want in mass production.

5. Aging Resistance for Long Service Life

Transformers and motors are expected to work for many years—sometimes decades. Acetate cloth tape is valued for its anti-aging performance, including:

-

Resistance to adhesive degradation

-

Stable insulation over time

-

Reduced brittleness compared to low-grade materials

This long-term reliability is why acetate cloth tape remains common even as new materials enter the market.

6. How It Works Together with Other Industrial Tapes

In real applications, acetate cloth tape rarely works alone.

A typical system might include:

-

Acetate cloth tape for internal insulation

-

Nylon cloth tape for outer wire bundling

-

Printable tape for wire identification

-

Conductive fabric tape for EMI shielding

Each tape handles a different function. Together, they create a balanced and efficient electrical protection system.

7. Customization Matters More Than You Think

Not all transformers or motors are the same. That’s why acetate cloth tape is often customized by:

-

Width and thickness

-

Color coding

-

Adhesive formulation

Working directly with a manufacturer allows buyers to match tape properties to specific electrical designs instead of settling for generic solutions.

Conclusion

Acetate cloth tape is widely used in transformers and motors because it offers the right combination of electrical insulation, heat resistance, flexibility, and long-term stability.

It may not be the strongest tape mechanically, but in controlled electrical environments, it performs exactly as needed. When combined with nylon cloth tape, printable tape, and conductive fabric tape, it supports safe, efficient, and maintainable electrical systems.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance