Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

If you’ve ever opened an old motor, transformer, or electrical cabinet, you may have noticed one small detail that often decides everything: the condition of the tape.

Some tapes stay firmly in place after years of heat exposure, while others turn brittle, peel off, or even melt slightly. That difference usually comes down to heat resistance.

In previous blogs, we discussed how acetate cloth tape, nylon cloth tape, and printable tape support wiring organization and insulation. Today, let’s go one step deeper and answer a very practical question:

👉 Why does heat resistance matter so much when choosing tape for electrical equipment?

Heat Is a Daily Reality in Electrical Equipment

Electrical systems don’t fail because of sudden heat spikes alone. More often, damage comes from long-term, repeated exposure to moderate heat.

Common heat sources include:

-

Transformers running continuously

-

Motors under heavy load

-

Power supplies inside compact enclosures

-

Automotive engine compartments

-

Home appliances like refrigerators and air conditioners

Over time, even temperatures between 80°C–130°C can weaken a tape that wasn’t designed for it. And once tape fails, wires lose insulation, stability, and protection.

This is where heat-resistant industrial tapes quietly do their job.

What Happens When Tape Lacks Heat Resistance?

Using a tape with poor thermal stability can cause several real-world problems:

-

Adhesive softening

The glue may ooze, migrate, or lose bonding strength, causing tape to unwrap. -

Material hardening or cracking

Some backings become stiff or brittle under heat, making them break during vibration. -

Loss of insulation performance

Electrical insulation properties may degrade, increasing safety risks. -

Maintenance becomes harder

Melted adhesive leaves residue that is difficult to clean during repairs.

In short, the tape becomes the weak link, even if the wires themselves are still fine.

How Heat-Resistant Tape Improves Long-Term Reliability

Heat-resistant tapes are designed to stay stable under continuous thermal stress. Their advantages show up slowly—but clearly—over time.

Key benefits include:

-

Stable adhesion at elevated temperatures

-

Consistent insulation performance

-

Resistance to aging and oxidation

-

Reduced need for rework or replacement

This is why professional manufacturers don’t choose tape based on appearance or price alone, they look closely at thermal ratings.

Comparing Common Heat-Resistant Tape Options

Based on applications we’ve discussed before, here’s how different tapes handle heat in electrical environments.

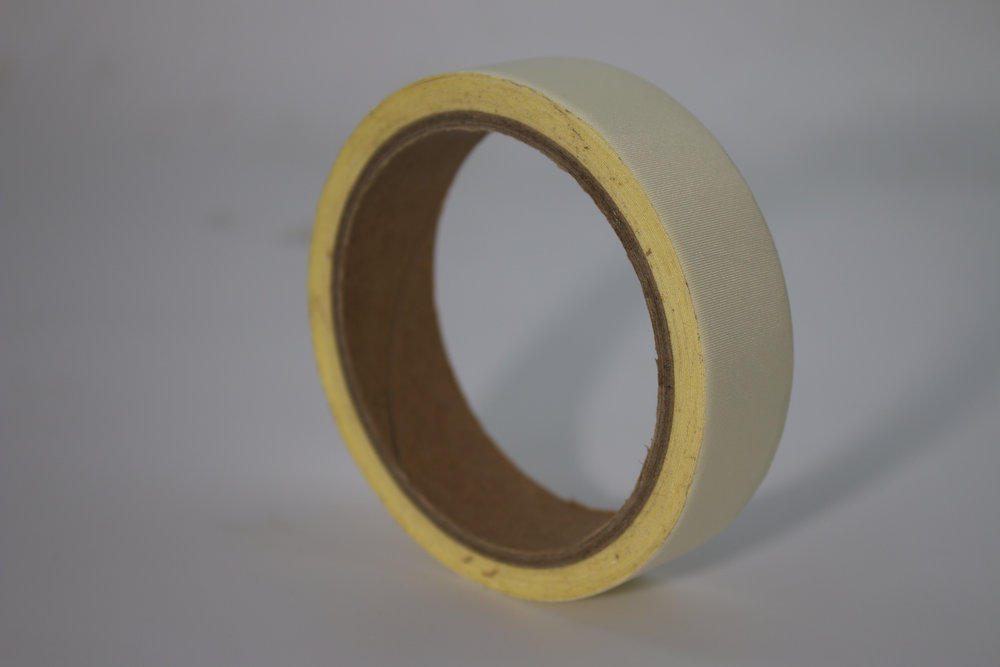

Acetate Cloth Tape

-

Typical temperature resistance: up to 105°C

-

Excellent conformability

-

Strong dielectric properties

-

Widely used in transformers and motors

This tape is often chosen where flexibility and insulation matter most.

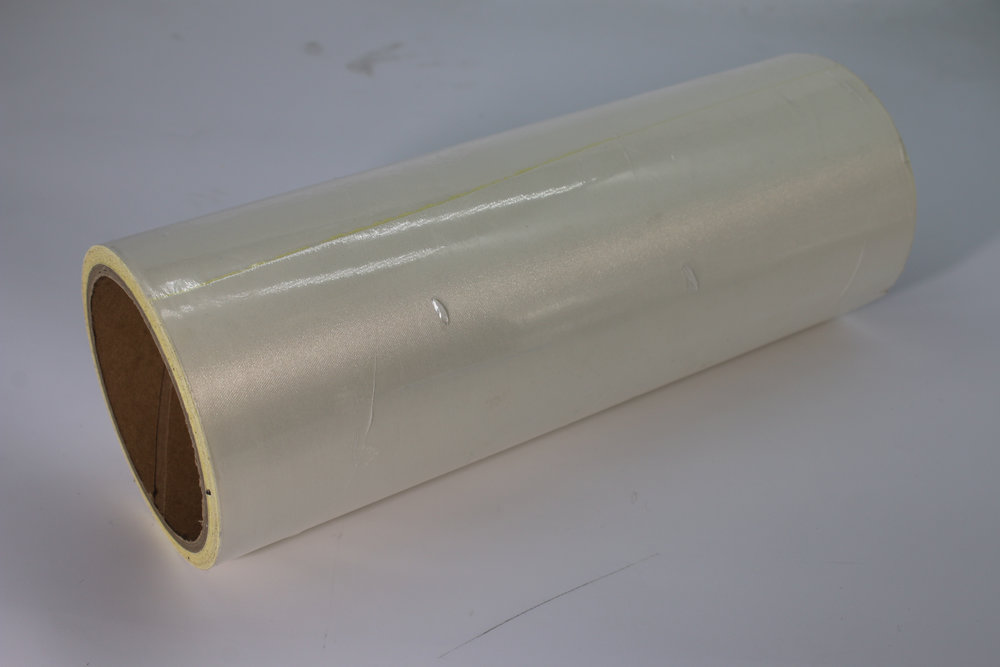

Nylon Cloth Tape

-

Temperature resistance: up to 125°C

-

High abrasion resistance

-

Strong mechanical strength

-

Common in wire harnesses and automotive systems

It holds bundles tightly even under heat and vibration.

Conductive Cloth Tape (for EMI shielding)

-

Designed to perform under heat while maintaining conductivity

-

Used in electronic shielding, displays, and control systems

Each type serves a different role, but heat resistance is always part of the decision.

Heat Resistance Also Affects Safety Compliance

Many industries must meet strict safety and quality standards. Using the wrong tape can cause a product to fail inspection.

Heat-resistant tapes help support:

-

Electrical safety certifications

-

Long-term product reliability

-

Reduced warranty claims

-

Stable performance in export markets

Sometimes a tape may look the same, but it behave very differently after months of heat exposure.

Choosing the Right Tape Starts with Understanding Heat Conditions

Before selecting a tape, it helps to ask a few simple questions:

-

What is the maximum operating temperature?

-

Is heat constant or intermittent?

-

Will there be vibration or movement?

-

Is insulation, bundling, or shielding the main goal?

Once these are clear, choosing between acetate cloth tape, nylon cloth tape, or other functional tapes becomes much easier.

Final Thoughts

Heat resistance isn’t just a technical parameter on a datasheet. It directly affects how long electrical equipment stays safe, stable, and easy to maintain.

Whether you’re working on transformers, motors, automotive wiring, or consumer electronics, choosing the right heat-resistant tape is a small decision that prevents big problems later.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance