Conductive Tape vs Insulating Tape: When Do You Need Both?

When it comes to electrical and electronic projects, many people wonder whether they should use conductive tape or insulating tape. Some engineers think one type of tape is enough, but in reality, there are scenarios where both tapes work together to ensure safety, performance, and longevity.

In our previous posts, we explored heat resistance in tapes and compared conductive cloth tape vs aluminum foil tape. Now, let’s dive into why sometimes using both conductive and insulating tapes is the smartest choice.

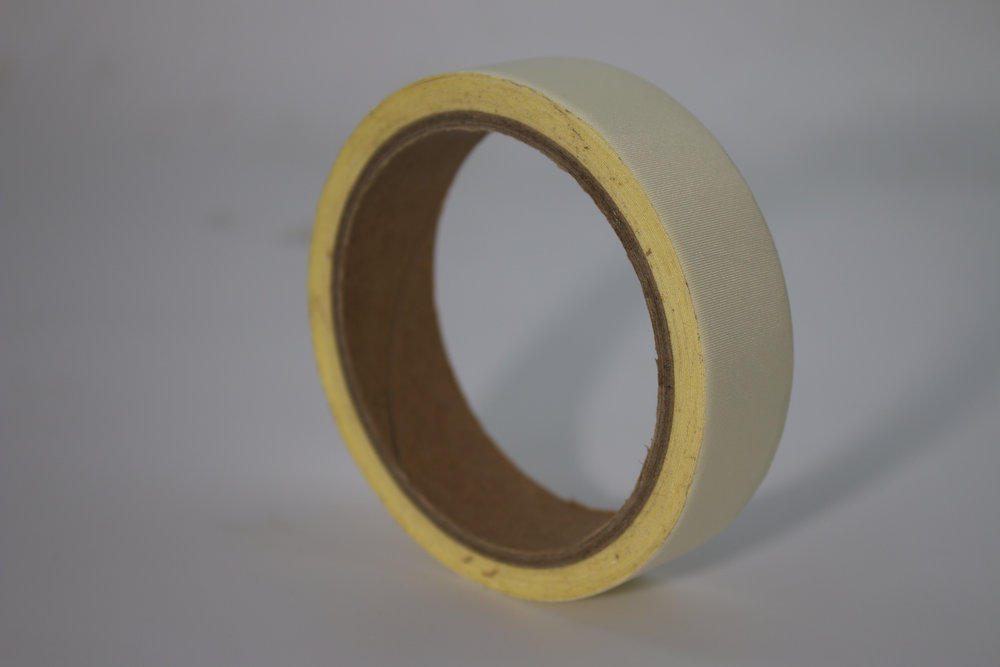

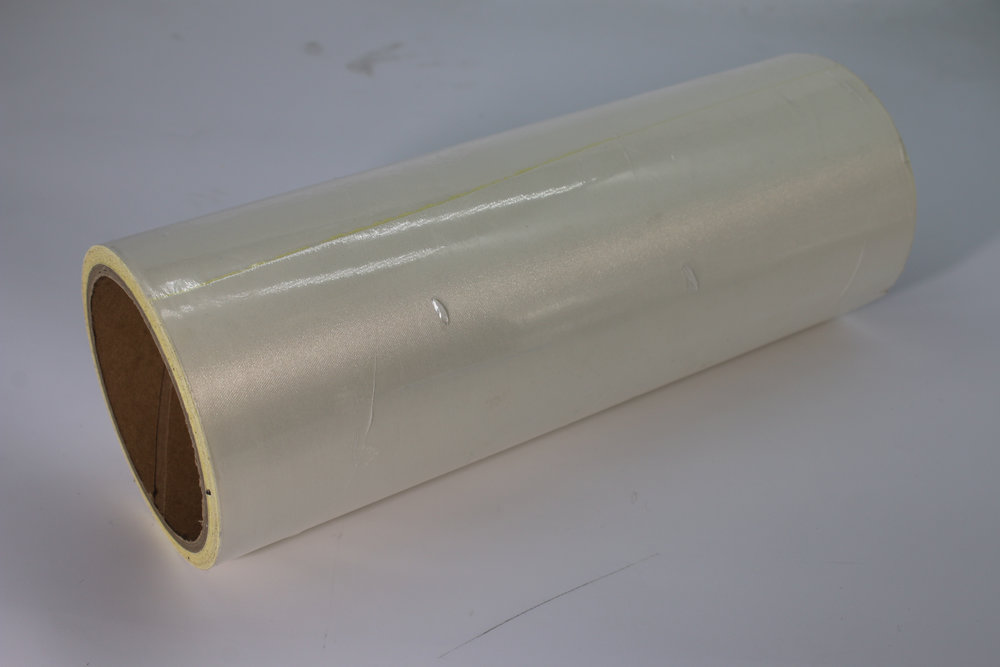

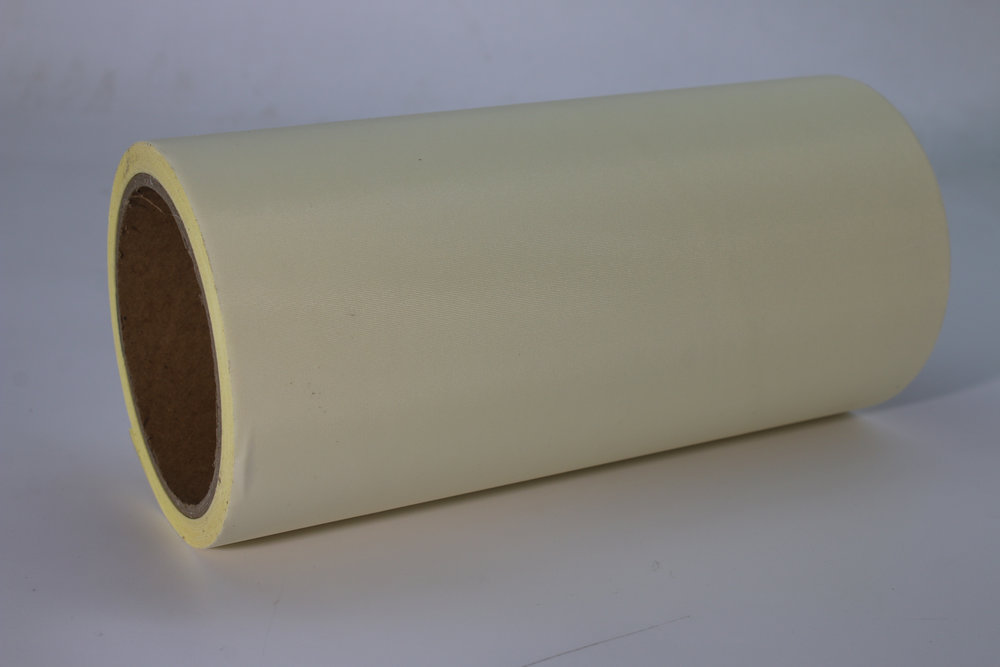

Understanding Conductive Tape

Conductive tape is designed to carry or block electrical currents, provide EMI/RFI shielding, and sometimes even aid in grounding. Common applications include:

-

Shielding cables in electronics

-

Covering sensitive circuits in devices

-

Preventing electromagnetic interference in automotive electronics

Conductive tapes often use a cloth or metal foil backing with conductive adhesive. While they excel at conduction and shielding, they cannot protect against accidental short circuits if exposed bare.

Understanding Insulating Tape

Insulating tape, on the other hand, is non-conductive and protects circuits from accidental electrical contact. It:

-

Prevents short circuits

-

Provides electrical isolation

-

Can be heat resistant and flame retardant

Materials commonly used include acetate cloth, PVC, or high-temperature polyimide. While insulating tape is great for safety, it cannot conduct electricity or block EMI.

When Both Are Needed

So, when do you need both conductive and insulating tape?

-

EMI-sensitive circuits inside high-power electronics

-

Conductive tape shields against interference

-

Insulating tape ensures exposed conductive areas don’t cause shorts

-

-

Automotive wire harnesses in engine compartments

-

Conductive tape can manage EMI from sensors and motors

-

Insulating tape protects against vibration, heat, and accidental contact

-

-

Transformers, motors, and power supplies

-

Conductive tape helps maintain grounding and EMI shielding

-

Insulating tape separates layers of windings or protects mounting areas

-

Using both tapes strategically ensures performance, safety, and long-term reliability.

Practical Tips for Using Both Tapes

-

Layering order matters: Apply conductive tape first for shielding, then insulating tape on top for safety.

-

Check temperature ratings: Both tapes should withstand the device’s operating heat.

-

Avoid adhesive conflicts: Make sure the insulating tape sticks well to the conductive tape.

-

Size and width: Use wide enough tape for complete coverage but narrow enough to fit tight spaces.

These simple tips can save a lot of time and troubleshooting down the road.

Benefits of Using Both Together

-

Maximizes EMI protection

-

Prevents short circuits in high-power or sensitive devices

-

Improves durability under heat, vibration, and movement

-

Offers modular maintenance – tapes can be replaced separately

For engineers and technicians, this is a proven approach in electronics assembly, automotive wiring, and industrial equipment.

Conclusion

Conductive tape and insulating tape are not mutually exclusive. In fact, in many applications, using both tapes together is the best practice for safety, reliability, and performance. Understanding when to combine them ensures your devices operate smoothly, last longer, and remain safe under stress.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance