Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

In our previous blogs, we discussed how nylon cloth tape helps keep wire bundles secure, and how different industrial tapes protect cables from vibration, heat, and interference. But even when wires are well protected, another problem often shows up later during maintenance: no one knows which cable is which.

That’s where printable tape quietly becomes a game changer.

1. Why Wiring Identification Is More Important Than People Think

At the beginning of a project—whether it’s an electrical cabinet, automotive system, or home appliance—everything looks clean and organized. But months or years later, when repairs or upgrades are needed, unclear wiring can cause:

-

Longer maintenance time

-

Higher risk of wrong connections

-

Increased labor costs

-

Unnecessary system downtime

Let’s be honest, nobody enjoys guessing which wire does what. Clear labeling simply saves time and avoids mistakes.

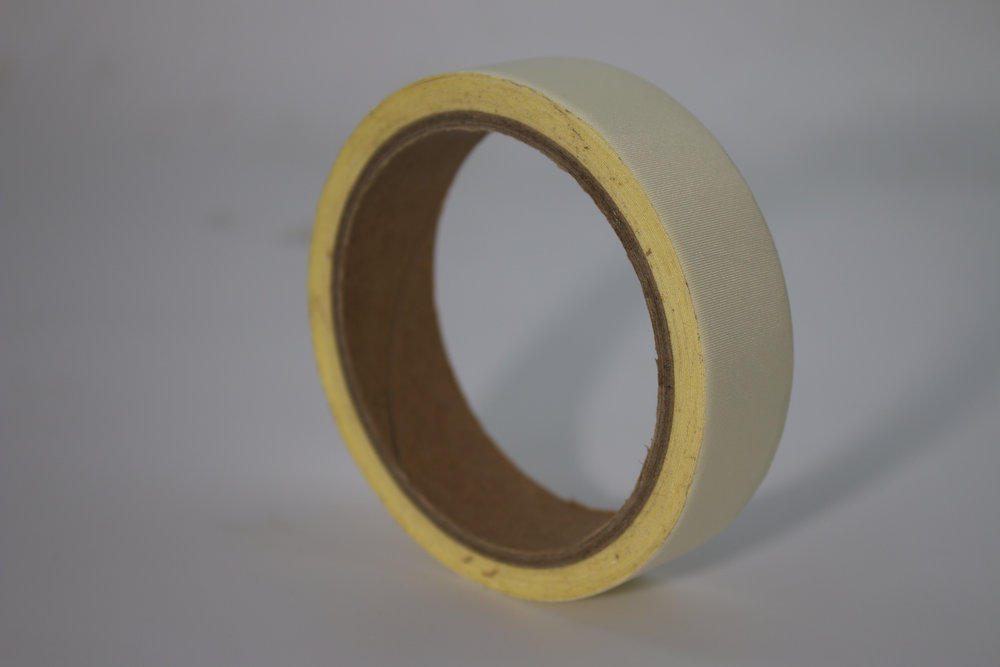

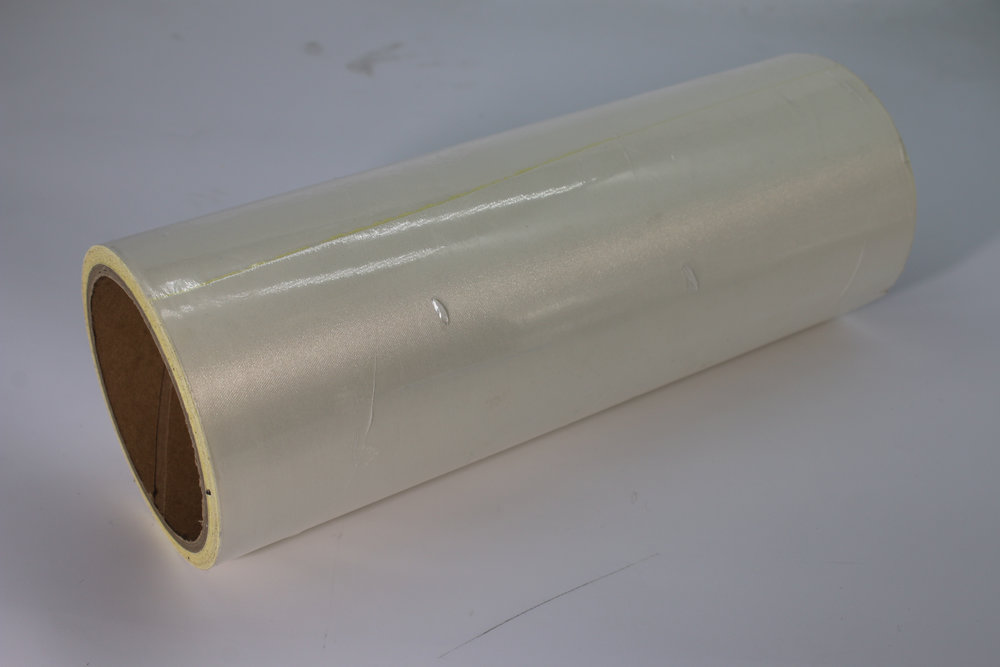

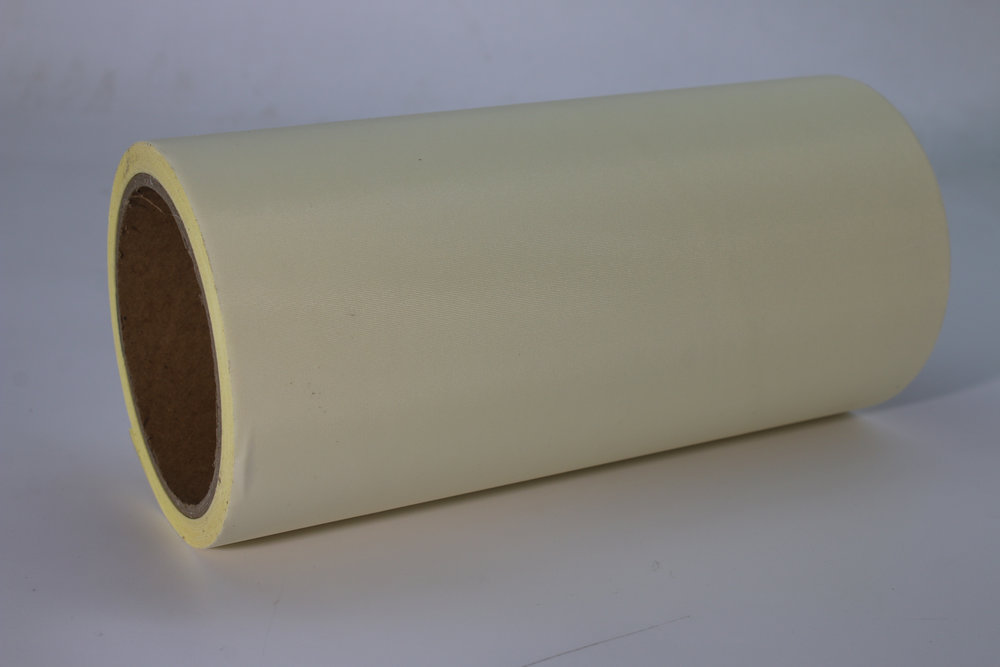

2. What Is Printable Tape and How Does It Work?

Printable tape is a specially designed adhesive tape that allows text, symbols, barcodes, or color codes to be printed directly onto the tape surface. Once applied, the label becomes part of the wire bundle.

Compared with traditional tags or paper labels, printable tape offers:

-

Strong adhesion that doesn’t fall off

-

Resistance to oil, heat, and abrasion

-

Clean, professional appearance

-

Long-term readability

When used together with nylon cloth tape or automotive wire harness tape, printable tape adds an identification layer without affecting flexibility or durability.

3. How Custom Labels Improve Daily Maintenance

Clear labeling might sound simple, but its impact is huge.

With printable tape, maintenance staff can instantly identify:

-

Power lines vs signal lines

-

Input and output cables

-

Different voltage levels

-

Specific circuit functions

This means troubleshooting becomes faster, safer, and more accurate. And honestly, when everything is clearly marked, even complex systems feel less stressful to work on.

4. Practical Applications Across Industries

Printable tape is widely used in industries where cable clarity matters most:

-

Electronics: internal wiring of TVs, computers, and displays

-

Automotive: wire harness identification for assembly and repair

-

Home appliances: refrigerators, air conditioners, and transformers

-

Industrial equipment: control panels and electrical cabinets

In many cases, printable tape is applied after conductive fabric tape or light-blocking tape, ensuring both performance and clarity are covered in one system.

5. Designed for Long-Term Readability

One major issue with low-quality labels is fading or peeling over time. High-performance printable tape is designed to:

-

Maintain print clarity under heat and humidity

-

Resist smudging and chemical exposure

-

Stay readable even after years of service

This makes it ideal for long-life products where wiring is not meant to be replaced frequently. A label that disappears is no label at all, right?

6. Easy Customization for Different Needs

Printable tape can be customized in many ways, including:

-

Different widths for various cable sizes

-

Custom colors for quick visual identification

-

Specific text formats or numbering systems

This flexibility allows manufacturers and users to build their own labeling standards. Once set, maintenance becomes much more predictable, and things run smoother than before. Sometimes it’s the small details that make the biggest difference, it really help more than expected.

Printable tape may not be the most visible part of a wiring system, but it plays a critical role in long-term efficiency. By improving wiring identification, it reduces maintenance time, lowers error rates, and enhances overall system reliability.

When combined with nylon cloth tape, automotive wire harness tape, and conductive fabric tape, printable tape completes a practical and professional cable management solution—from protection to identification.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance