How to Customize Die-Cut Tape for Electronics Assembly: A U.S. Buyer's Guide

When it comes to electronics assembly, precision is everything. Whether you're building smartphones, smartwatches, or circuit boards, your adhesive solution needs to be just as advanced as your tech. That's where custom die-cut tape really shines. In this post, we’ll dive into how U.S. electronics manufacturers can get the perfect-fit die-cut tape from a China-based supplier, saving time and cutting costs.

Why Electronics Need Die-Cut Tape

In electronics manufacturing, adhesives do more than stick parts together. They provide insulation, EMI shielding, thermal conductivity, shock absorption, and even flame resistance. But here's the thing: generic tape just won’t do.

Die-cut tape allows for ultra-precise application with no trimming, no waste, and no room for error. From mounting camera modules to insulating batteries, die-cut tapes are your go-to invisible helper.

Key Properties for Electronics Die-Cut Tape

When customizing die-cut tape for electronics, U.S. buyers should consider:

-

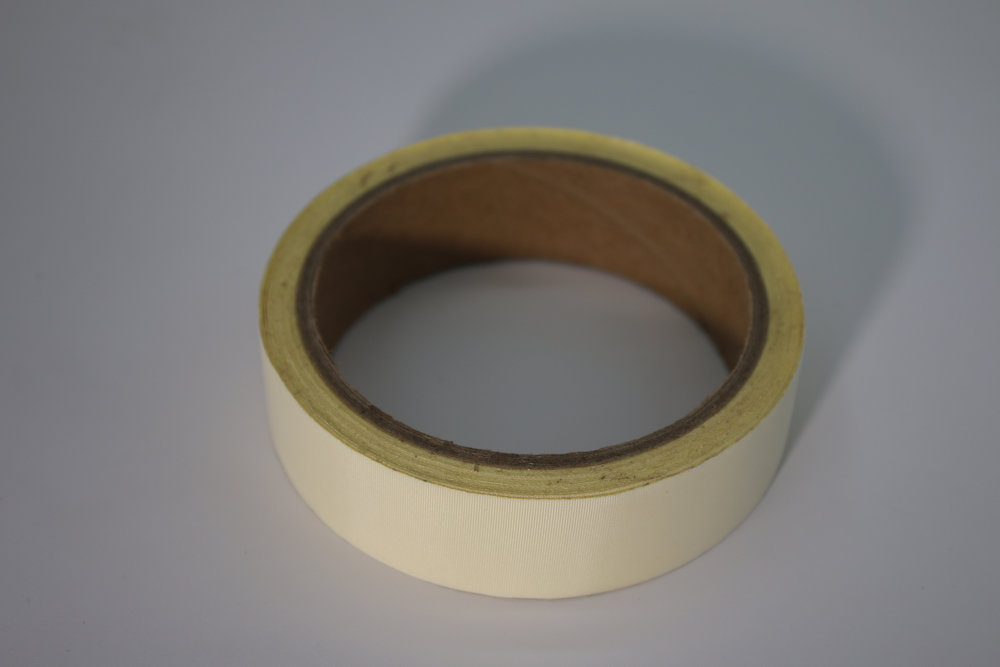

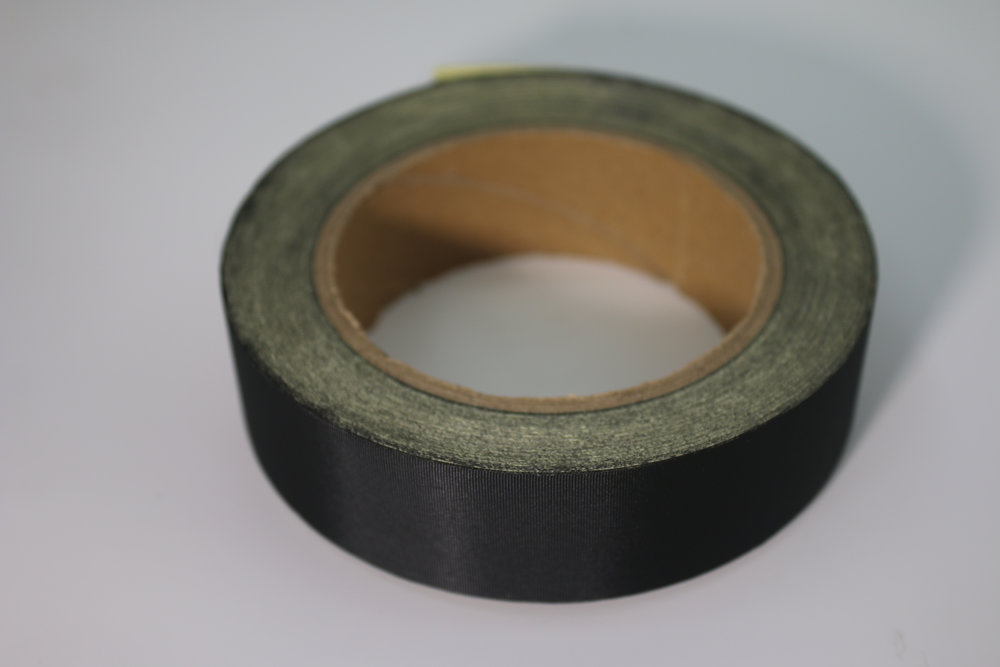

Material: PET, PI (polyimide), foam, copper foil, or conductive fabric

-

Adhesive Type: Acrylic (permanent), silicone (heat-resistant), or rubber (flexible)

-

Thickness: Ultra-thin 0.05mm for tight spaces to 1mm foam for cushioning

-

Tolerance: ±0.1mm or better for high-precision components

-

Special Properties: Flame retardant, anti-static, low VOC, RoHS/UL approved

By customizing these parameters, you get tape that performs exactly as needed—without compromising your design.

Customization Options Offered by Chinese Factories

Sourcing from a Chinese die-cut tape manufacturer? Here's what we typically offer:

-

Custom shapes (L-shape, ring, U-shape, etc.)

-

Perforated or tabbed designs for easy peel

-

Multi-layer laminations (with PET liner, release film, or double-sided layers)

-

Anti-static or EMI shielding layers

-

Roll-fed or sheet formats

Plus, most suppliers (including us) offer free samples or prototyping for bulk orders. So you don’t gotta worry about trying before buying.

Real-World Applications in Electronics

Let’s take a quick look at how die-cut tapes are actually used in devices:

-

Smartphones/Tablets: camera foam rings, speaker mesh adhesives

-

Laptops/PCBs: insulating polyimide die-cuts between components

-

LEDs/Displays: thermal conductive tapes for heat dissipation

-

Battery Packs: flame-retardant adhesive for lithium-ion safety

-

EMI Solutions: conductive fabric tapes for shielding sensitive signals

Pretty neat, right?

Tips for U.S. Buyers When Ordering Custom Die-Cut Tape

Ordering from overseas doesn’t have to be scary. Just follow these tips:

-

🔹 Always send a CAD or DXF drawing with tolerances marked

-

🔹 Ask about available tooling options (flatbed, rotary, laser)

-

🔹 Confirm adhesive specs match your environmental conditions (heat, humidity)

-

🔹 Request a pre-production sample if ordering 10k+ pcs

-

🔹 Choose suppliers with full in-house production to avoid quality inconsistency

Why Choose a China Manufacturer for Die-Cut Tape?

Truth be told, many U.S. converters mark up die-cut tapes heavily. When you work with a China-based factory supplier like us, you cut out the middleman and get:

-

Lower unit cost

-

Fast lead times

-

Flexible customization

-

One-stop support (materials + cutting)

And our team knows how to work with international engineering standards.

Conclusion

For U.S. electronics manufacturers, custom die-cut tape is more than just a sticking solution—it's a performance component. By working directly with a die-cut tape supplier in China, you gain access to custom materials, precision cutting, and OEM-level support.

If you’re sourcing for your electronics project, let’s talk specs!

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures