Why Are Nylon Cloth Tapes and Die-Cut Tapes Essential for Automotive and Industrial Applications?

When it comes to automotive assembly, industrial maintenance, and electronics manufacturing, many engineers and procurement managers often overlook the crucial role of specialty tapes. But have you ever thought about why nylon cloth tapes and die-cut tapes are so widely used? Let’s break it down.

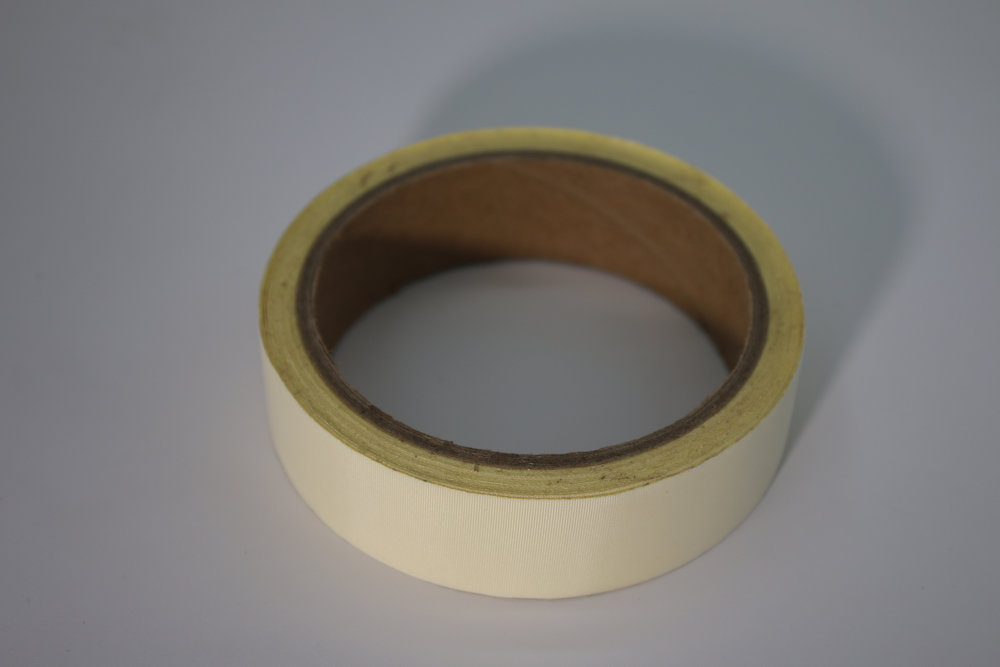

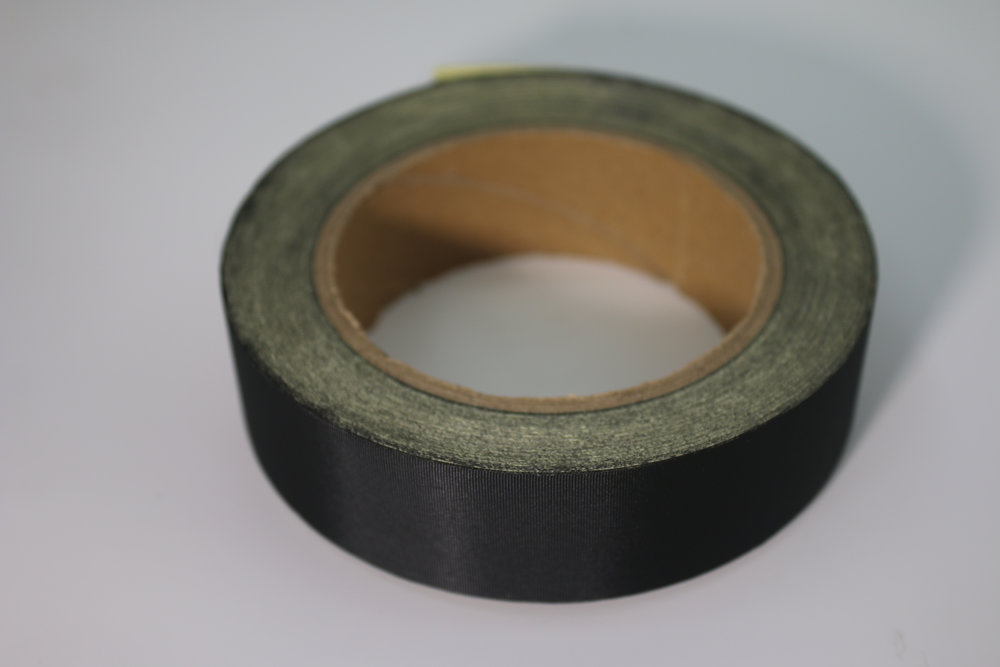

The Strength of Nylon Cloth Tapes

Nylon cloth tapes are known for their high tensile strength, flexibility, and durability, making them ideal for heavy-duty applications. Key uses include:

-

Automotive wire harness bundling: Secures wiring in engine compartments and prevents abrasion.

-

Industrial pipe and equipment sealing: Provides anti-slip and waterproof protection.

-

Electronics assembly: Offers electrical insulation and protects delicate components.

-

Outdoor and marine applications: Resistant to UV, corrosion, and extreme temperatures.

Thanks to factory-direct suppliers in China, nylon cloth tapes can be customized in color, width, thickness, and adhesive type, allowing businesses to optimize their workflows efficiently.

Die-Cut Tapes: Precision and Versatility

Die-cut tapes are pre-cut into specific shapes and sizes, offering precise application and saving labor time. Common applications include:

-

Automotive sensors and connectors: Die-cut shapes fit perfectly for protection and insulation.

-

PCB and electronic components: Provides shielding against EMI and mechanical support.

-

Industrial equipment assembly: Multi-layer or adhesive-backed die-cut tapes enhance structural stability.

-

Medical and laboratory equipment: Ensures hygienic and precise sealing without residue.

Die-cut tapes can be made from foam, PET, cloth, or conductive materials, and Chinese manufacturers can provide OEM solutions for small or large batches, meeting both prototyping and mass production needs.

Why Combined Solutions Work Better

Many companies find that using nylon cloth tapes alongside die-cut tapes offers several benefits:

-

Enhanced protection: Nylon cloth tapes protect against wear and tear, while die-cut tapes provide precise placement.

-

Time efficiency: Pre-cut shapes save manual labor during assembly.

-

Customizable performance: Adhesive strength, thickness, and material type can be tailored to industrial or automotive specifications.

This combination ensures high-quality results, reduces errors, and improves overall productivity.

Advantages of Sourcing from China-Based Manufacturers

Partnering with a China-based supplier like Anhui Yijiayi Technology Co., Ltd. provides:

-

Factory-direct pricing for bulk and OEM orders.

-

Customizable solutions for nylon cloth tapes and die-cut tapes in various materials, shapes, and sizes.

-

Wide product selection including conductive tapes, acetate cloth tapes, printable tapes, and light-blocking tapes.

-

Reliable supply chain for industrial, automotive, and electronics sectors.

By sourcing directly, companies save costs while ensuring consistent quality and customization for their specific applications.

Nylon cloth tapes and die-cut tapes are indispensable in automotive, industrial, and electronics manufacturing. They provide strength, precision, and flexibility, helping businesses reduce errors, protect components, and optimize workflows.

Partnering with a trusted China-based manufacturer and supplier ensures that companies receive customizable, high-quality, and factory-direct tape solutions, ready for any industrial or automotive challenge.

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

How Often Should Electrical Tape Be Replaced in Industrial Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

Nylon Cloth Tape vs Acetate Cloth Tape: Which Is Better for Control Cabinets?

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

5 Signs Your Electrical Tape Is Failing Inside Control Cabinets

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Why Nylon Cloth Tape Is Preferred for Industrial Control Panels?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

Cloth Tape vs PVC Tape: Which Lasts Longer in Control Cabinets?

How Long Does Electrical Tape Really Last in Industrial Environments?

How Long Does Electrical Tape Really Last in Industrial Environments?

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

Common Electrical Tape Failures and How to Avoid Them in Industrial Use

How to Improve Electrical Safety with Proper Tape Selection

How to Improve Electrical Safety with Proper Tape Selection

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures