How Can High-Performance Adhesive Tapes Improve Electronic Devices Reliability?

Electronics today are smaller, faster, and more complex than ever. From smartphones to industrial machinery, every device depends on high-performance adhesive tapes to stay functional and safe. But how exactly do these tapes make a difference, and why should manufacturers care? Let’s break it down.

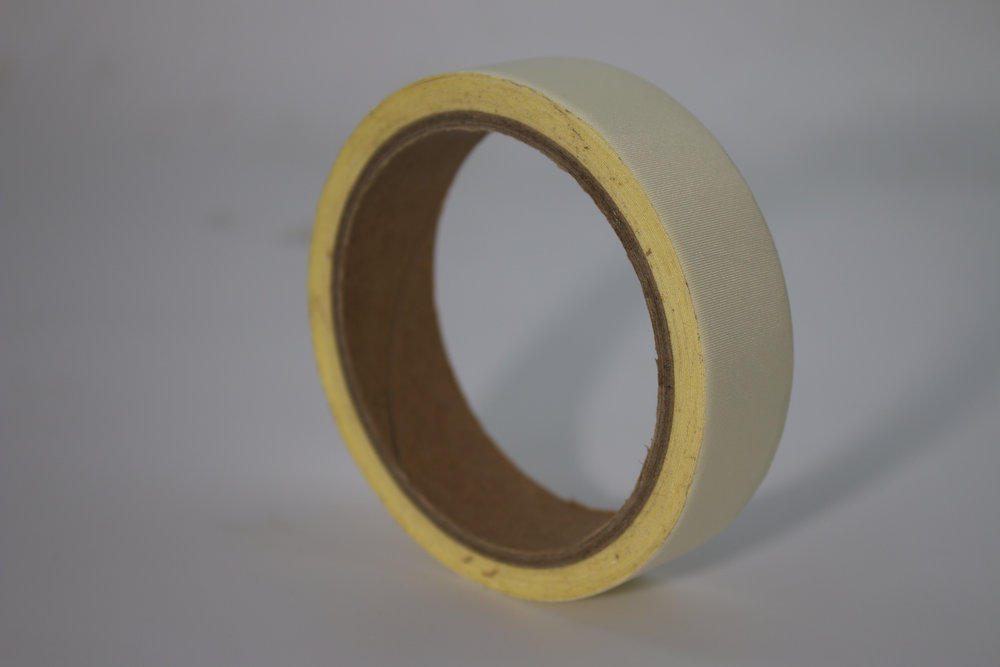

Conductive Fabric Tape: Shielding Against Interference

Electromagnetic interference (EMI) is a hidden problem in electronics, affecting performance and reliability. Conductive fabric tapes are specifically engineered to shield sensitive circuits and prevent signal disruption. Manufacturers use these tapes in PCBs, sensors, and high-frequency devices, ensuring products meet global standards.

Acetate Cloth Tape: Insulation and Safety

Insulation is key in electronics. Acetate cloth tapes provide high-temperature resistance, electrical insulation, and flame retardancy, protecting circuits from heat and short circuits. Whether in power modules, battery packs, or industrial controllers, these tapes reduce the risk of failure and enhance device longevity.

Nylon Cloth Tape: Durability and Flexibility

Electronics often require tapes that can withstand abrasion, bending, and repeated assembly processes. Nylon cloth tapes offer strong adhesion and durability, making them perfect for wiring bundles, component protection, and device assembly. Their flexibility also makes installation faster — saving both time and labor costs.

Die-Cut Tapes: Precision for Small Components

When devices are miniaturized, standard tape rolls are not enough. Die-cut tapes allow for custom shapes and sizes, fitting perfectly onto complex parts. They are used in touch screens, LED modules, cameras, and other compact electronics, ensuring reliable attachment and protection without excess material.

Light-Blocking & Printable Tapes: Functional Design

Some electronic applications require light-blocking solutions, such as camera modules or optical sensors. Others benefit from printable tapes for labeling, safety marks, or assembly guidance. By integrating these tapes, manufacturers can enhance product functionality, traceability, and quality control.

Why Source Directly from a China Manufacturer?

Partnering with a China-based adhesive tape manufacturer and supplier like Anhui Yijiayi Technology Co., Ltd. offers distinct advantages:

-

Direct factory pricing for bulk orders

-

OEM customization for tape dimensions, adhesion strength, and materials

-

Compliance with international standards (ROHS, UL, ISO)

-

Wide product selection covering conductive, nylon, acetate, die-cut, and printable tapes

-

Reliable technical support for industrial applications

This means manufacturers can get exactly what they need — fast, reliably, and cost-effectively.

In electronics, every millimeter of adhesive tape counts. From EMI shielding to insulation, durability, precision die-cuts, and functional labeling, high-performance tapes play a critical role in device reliability and manufacturing efficiency. Choosing the right supplier ensures access to customizable, high-quality tapes, keeping products safe and competitive.

At Anhui Yijiayi Technology Co., Ltd., we specialize in direct factory sales, OEM customization, and wholesale supply, serving global electronics manufacturers as a trusted China supplier.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance