How Printable Tape Improves Labeling Efficiency Across Industries?

Labeling is a small step in manufacturing and logistics, yet it has a massive impact on organization, compliance, and brand recognition. At Anhui Yijiayi Technology Co., Ltd., our Printable Tape Series is designed to help businesses achieve precise labeling while maintaining durability and clarity. Let’s explore how this versatile tape can optimize your operations.

1. What Makes Printable Tape Special?

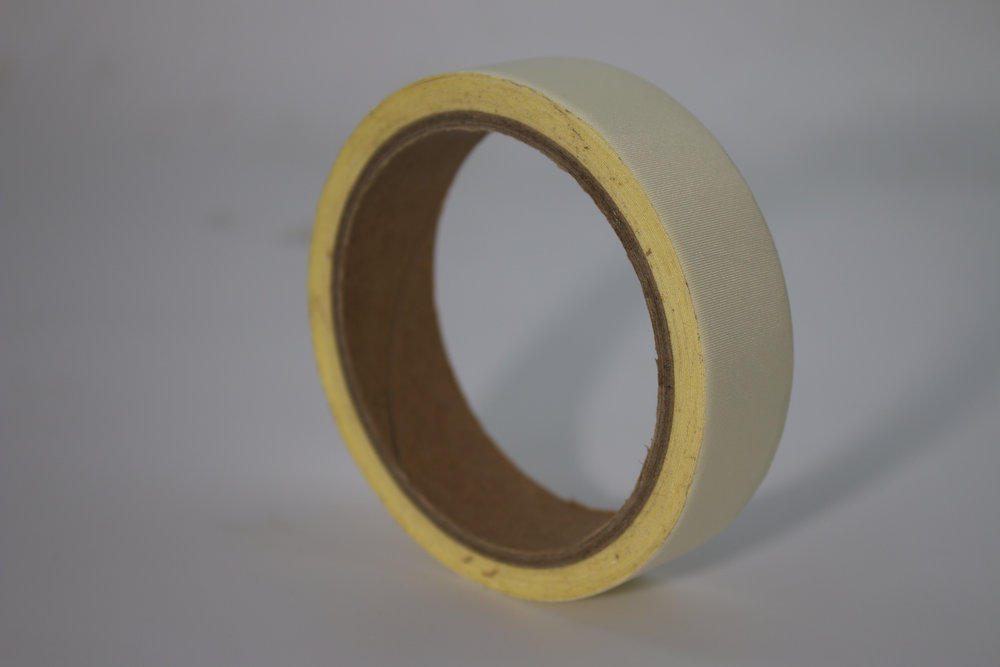

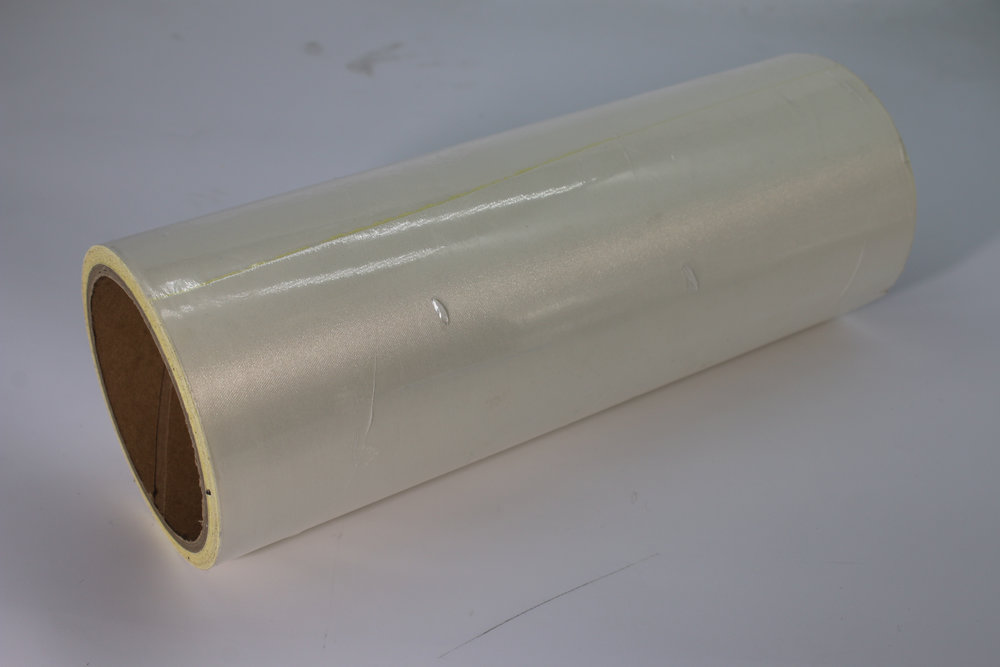

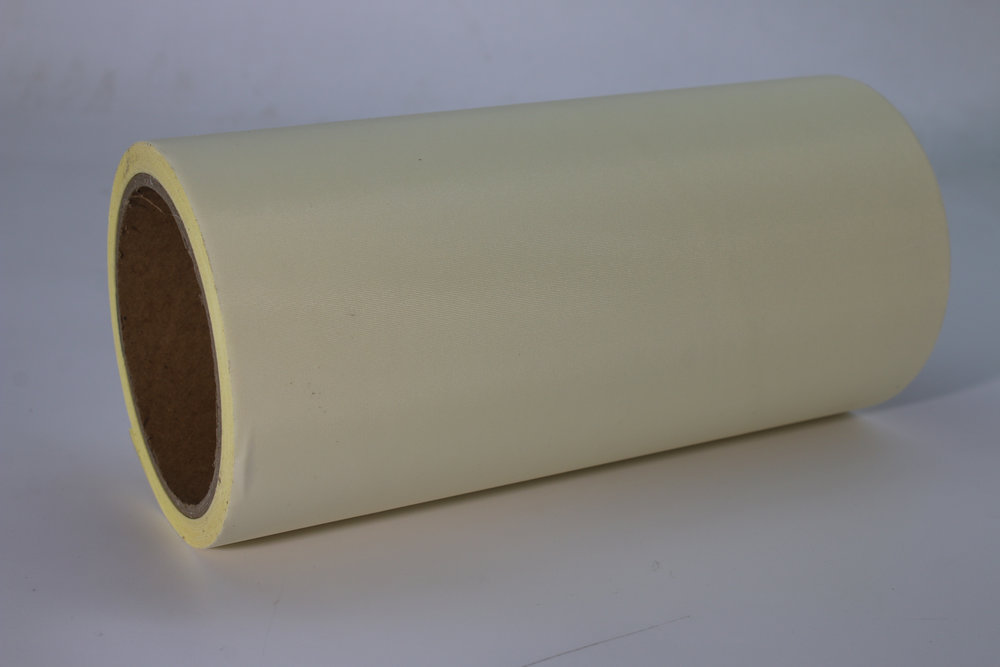

Unlike standard adhesive tapes, Printable Tape is engineered to accept high-resolution printing, including text, barcodes, QR codes, and logos. Available in PET, PVC, and paper-based variants, it supports various printing technologies:

-

Laser and inkjet printers

-

Thermal transfer and direct thermal printers

-

Labeling machines (Brother P-Touch, Epson, Canon, etc.)

This adaptability ensures consistent labeling quality across different equipment and industries, making it a go-to solution for B2B clients.

2. Applications That Benefit Most

Printable Tape is widely used in industries where precise identification and tracking matter:

-

Logistics & Warehousing: Clear, durable tape for packages, shelves, and racks.

-

Laboratories & Healthcare: Resistant to low temperatures, chemicals, and sterilization processes.

-

Automotive Parts & Electronics: Oil-resistant and heat-tolerant tapes for component identification.

-

Food Packaging: Safe, FDA-compliant tapes suitable for food labels.

When paired with Die-Cut Tape or Conductive Fabric Tape, you can create integrated solutions that combine labeling, insulation, and electromagnetic shielding in complex electronic assemblies.

3. Advantages That Improve Efficiency

Businesses that adopt Printable Tape enjoy several benefits:

-

Reduced Errors: Clear, high-resolution printing minimizes mislabeling.

-

Time Savings: Easy to print and apply, reducing manual work.

-

Customization: Options for logos, color codes, and dimension adjustments.

-

Durability: Resistant to water, oil, UV, and extreme temperatures.

For instance, a warehouse using color-coded and printed tape can cut down retrieval errors and improve inventory management efficiency dramatically.

4. Choosing the Right Tape for Your Needs

Not all printable tapes are created equal. Key considerations include:

-

Material: PET for transparency, paper-based for eco-friendliness, or fluorescent for high visibility.

-

Adhesive Type: Permanent vs removable, depending on application.

-

Printing Compatibility: Make sure your printer type matches the tape.

-

Environment: Consider temperature, moisture, and chemical exposure.

At Yijiayi, we provide full customization for tape length, width, and adhesive type — ensuring your solution perfectly matches your production or labeling process.

5. Why Choose Yijiayi Printable Tape?

With over 53,000 square meters of manufacturing space, we independently control the production of raw materials, adhesive formulation, and finished tape processing. Our Printable Tape Series delivers high-performance results for diverse applications, from industrial machinery to everyday consumer electronics.

We also produce Light-Blocking Tape, Nylon Cloth Tape, Automotive Wire Harness Tape, and more — all designed to integrate seamlessly in complex projects.

Effective labeling is critical for productivity, compliance, and customer satisfaction. Printable Tape is a practical, versatile solution that not only makes labeling easier but also ensures long-term durability and clarity. By partnering with Anhui Yijiayi Technology Co., Ltd., businesses gain access to high-quality, customizable tapes directly from a trusted China manufacturer and supplier.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance