Printable Tape: How It Enhances Design and Functionality

In our previous blog, we discussed how conductive cloth tape protects electronics through EMI shielding. But the world of industrial adhesive tapes doesn’t stop there. Another rising star — printable tape — is changing the way designers, manufacturers, and even everyday users interact with labeling and identification.

Whether you’re designing packaging, assembling cables, or creating branded products, printable tape provides both function and aesthetics. So, how exactly does it work, and why is it becoming such a go-to material across industries?

1. What Is Printable Tape?

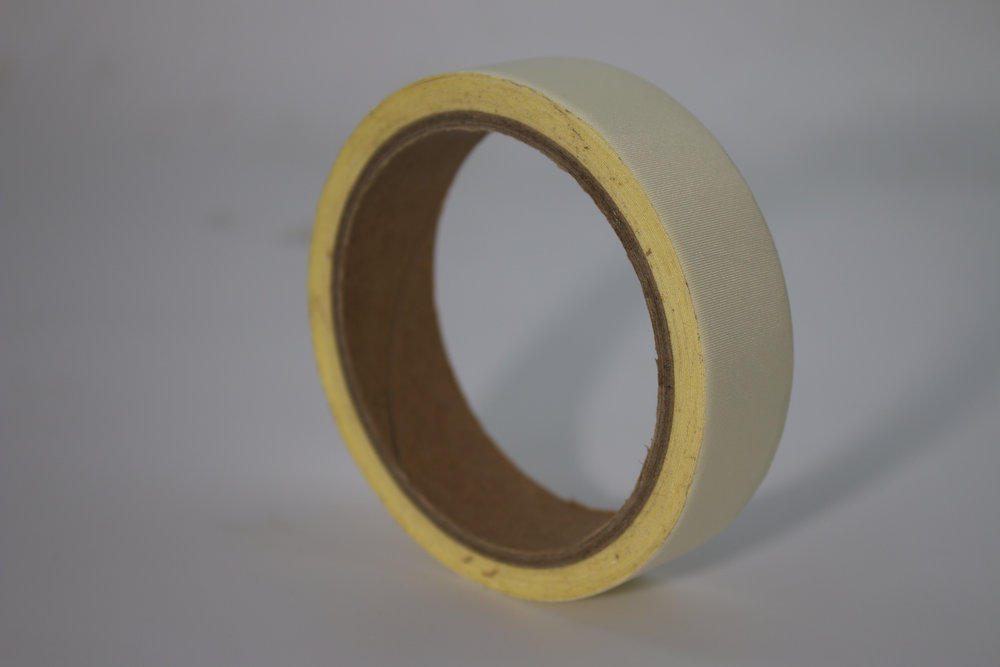

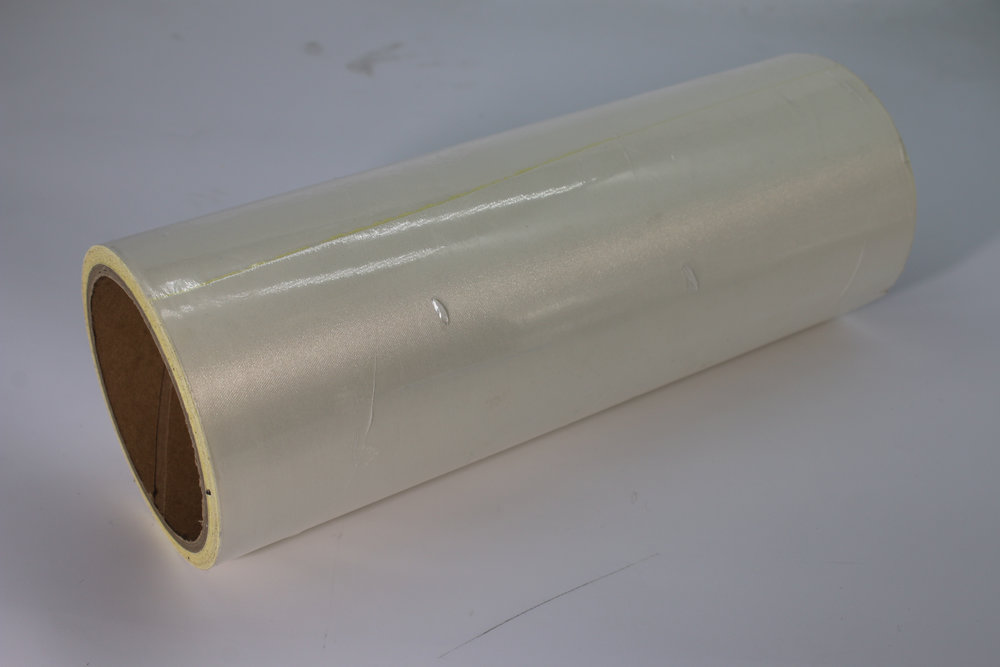

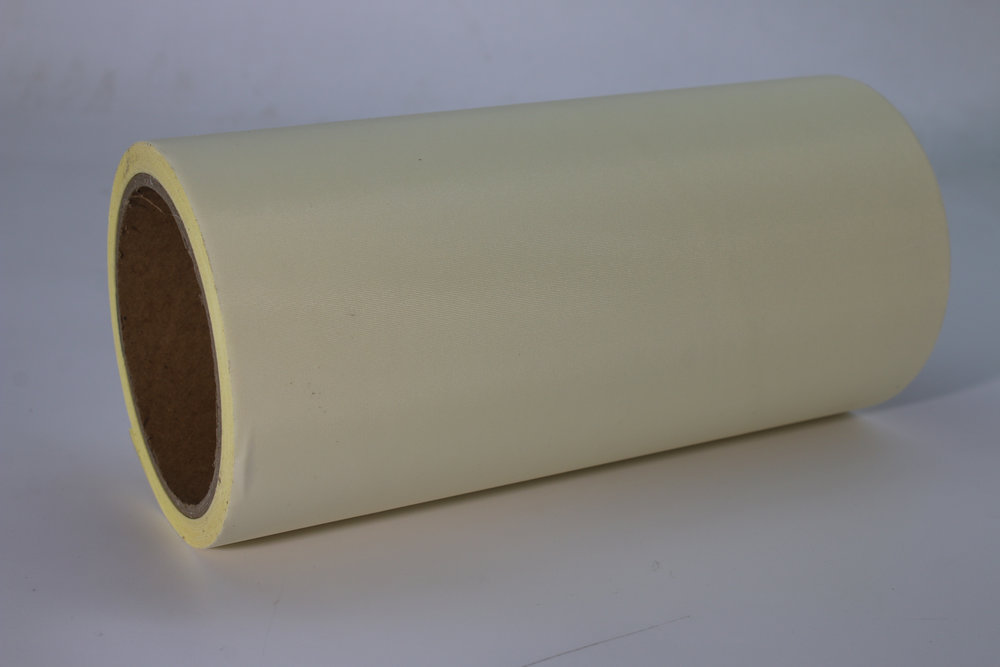

Printable tape is a specialized adhesive tape that allows text, patterns, or barcodes to be printed directly on its surface. It can be made from different base materials such as PET, PVC, or cloth, and coated with durable adhesives that resist wear, moisture, and heat.

Unlike traditional labels that peel off easily, printable tape is built to last. It bonds tightly to metal, glass, or plastic surfaces and withstands industrial environments — from electronic factories to automotive production lines.

Oh, and here’s a fun fact: printable tapes are also customizable. You can choose different colors, widths, and finishes — glossy, matte, or transparent — depending on your needs.

2. How Printable Tape Enhances Product Functionality

The most obvious advantage is clear identification. In manufacturing, workers need to label components, wires, or products accurately. Printable tape provides a clean surface for thermal transfer or ink printing, ensuring sharp and readable text.

In fact, many automotive and electronics companies use printable tapes to tag wire harnesses, connectors, and panels. When combined with the conductive cloth tapes we talked about earlier, it creates a complete system — one tape ensures EMI protection, while the other provides accurate labeling for maintenance or assembly.

That’s how these materials quietly support the efficiency behind modern production lines.

3. Why Manufacturers Love It

Let’s be honest — time is money in manufacturing. Printable tape helps save both. Instead of applying a separate label or sticker, factories can print directly onto the tape roll before or after applying it.

This means:

-

Less production time

-

Lower material cost

-

Cleaner appearance

Moreover, printable tapes can handle high temperatures and solvent exposure, making them ideal for harsh industrial conditions. Some even feature anti-static or flame-retardant properties for added safety — a big plus when dealing with electronics or automotive parts.

4. Everyday Applications of Printable Tape

Printable tape isn’t limited to factories. You can see it — sometimes without noticing — in your daily life:

-

Electronics: labeling cables or circuit boards

-

Automotive: identifying wiring harnesses or components

-

Logistics: marking cartons or inventory

-

Retail: customizing packaging with logos or safety messages

-

DIY projects: labeling tools or storage boxes

Pretty handy, right? It’s one of those small things that make a huge difference in keeping things organized and professional.

5. Customization Options by Yijiayi

At Anhui Yijiayi Technology Co., Ltd., we understand that every client has different printing and application needs. That’s why our Printable Tape Series comes in a wide range of materials and adhesive options.

We also support custom printing, die-cutting, and roll sizes, ensuring seamless integration with your production line. Whether you need heat-resistant labels for electronics or color-coded identification for wiring, we’ve got your back.

Plus, our printable tapes are made using eco-friendly formulations, which means less pollution and more sustainability — something we all care about nowadays.

6. The Future: Smart and Sustainable Printing Solutions

As industries shift toward smart manufacturing and automation, printable tapes are evolving too. New developments focus on digital printing compatibility, UV resistance, and sustainable adhesives that reduce carbon footprints.

Combining functionality, design, and durability, printable tape is becoming an essential material for next-generation production and packaging systems.

So, whether you’re in the electronics, automotive, or consumer goods industry, this is one small product that can make a big impact.

From EMI shielding with conductive cloth tape to precise identification with printable tape, the evolution of industrial adhesive materials continues to simplify and improve manufacturing.

And hey, that’s exactly what innovation should do — make things smarter, safer, and more efficient. Anhui Yijiayi Technology Co., Ltd., as a trusted China tape manufacturer, remains committed to offering high-quality, customizable, and sustainable tape solutions for businesses around the world.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance