Why Is Automotive Wire Harness Tape Important for EV and Vehicle Safety?

If you're sourcing automotive wire harness tape, especially for electric vehicles (EVs) or high-performance cars, you’ve probably wondered: Why does tape matter so much? This blog dives deep into its critical roles—from insulation and vibration resistance to flame retardancy—and explains why working with a China-based wire harness tape manufacturer can be a real game‑changer.

What Is Automotive Wire Harness Tape?

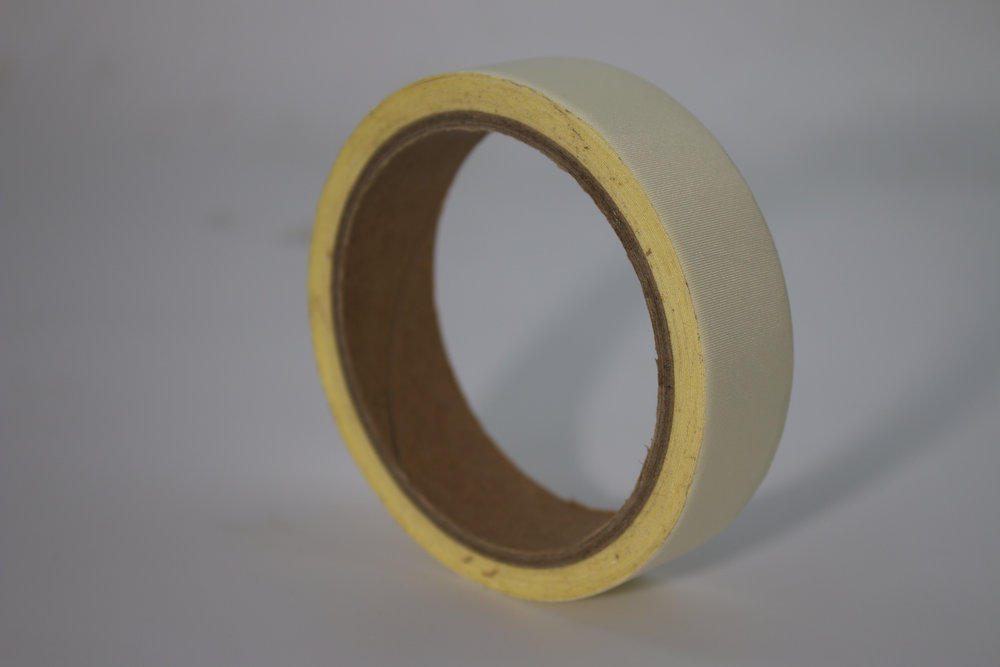

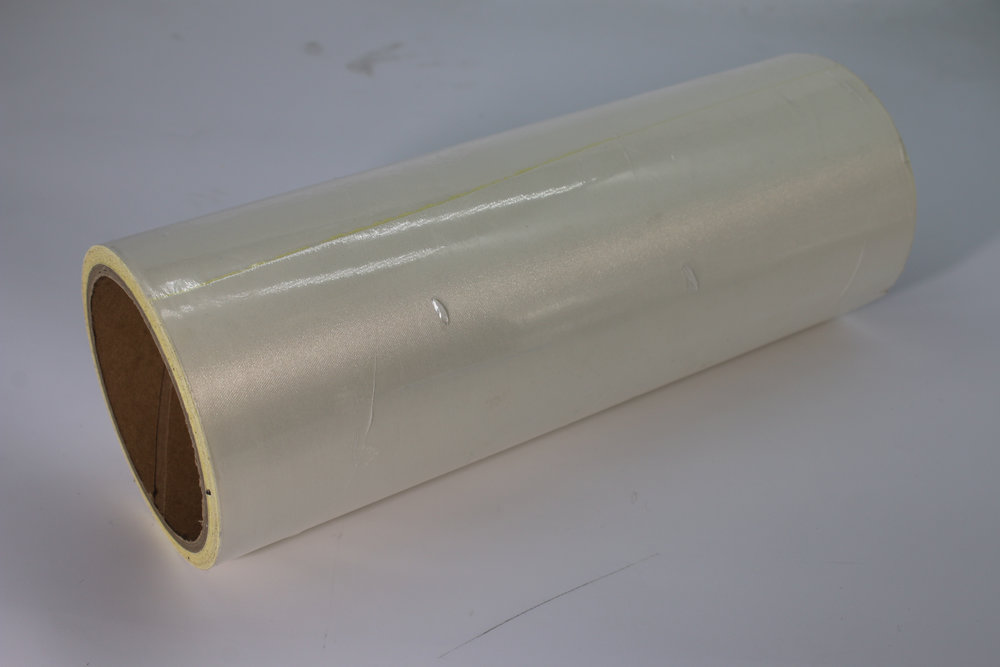

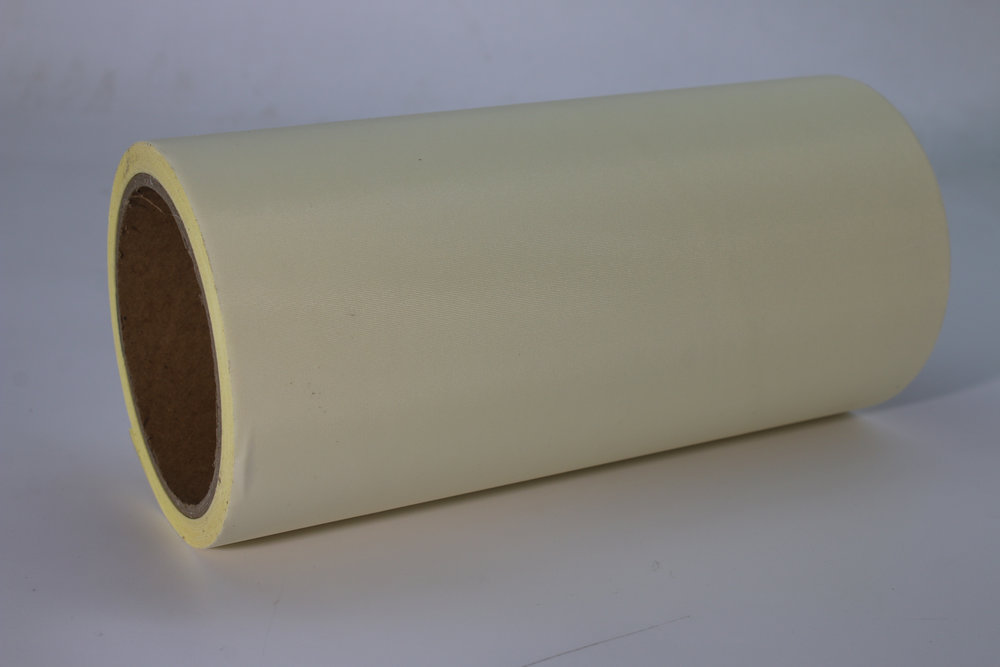

Automotive wire harness tape is a specialized cloth or film-backed adhesive tape designed to bundle, protect, and insulate electrical wire harnesses in vehicles. Typically made from polyester, nylon, acetate cloth or PET, and coated with acrylic or silicone adhesive, it’s flexible, durable, and suitable for rugged automotive conditions.

You might think tape is just tape—but no, not this kind. These are engineered for heat, abrasion, and even chemical exposure.

Key Functions in Automotive & EV Systems

1. Insulation & Protection

This tape protects bundles from rubbing, chafing and short circuits over time. In EVs, high-voltage cables especially need secure insulation.

2. Vibration Dampening

Under the hood or inside door panels, wire bundles are subject to vibration. A proper tape reduces noise and fatigue, keeping wiring intact.

3. Heat / Flame Resistance

Certain automotive tapes meet UL94 V‑0 or ISO fire safety standards. That’s essential for engine compartments, EV traction packs, or near heat-generating modules.

4. Moisture & Chemical Resistance

Modern EVs and vehicles are exposed to coolant, oils, road salt. Quality tape protected under warranty is crucial. Some tapes are also RoHS-compliant and low‑VOC.

Why Should U.S. Buyers Consider a China Factory Direct Supplier?

Many buyers get shocked when they see prices from local suppliers. Working with a China supplier and manufacturer of automotive wire harness tape can offer:

-

Bulk, low-cost, factory-direct wholesale supply

-

OEM/ODM customization of colors, widths, adhesive types

-

Speedy sampling and prototyping

-

Certifications like RoHS, UL, and ISO support

-

Low MOQ for testing runs

And yeah, you’re basically cutting out the middleman—or as we call it, cut the fluff.

How to Choose the Right Tape Spec?

When ordering, consider:

-

Base material: acetate cloth vs. PET vs. nylon

-

Tape thickness: usually 0.1mm to 0.25mm

-

Adhesive type: acrylic for high heat, rubber for general use

-

Flame rating: UL94 V-0 for EV packs, V-2 for interior

-

Environmental resistance: UV, oil, humidity

For EV harnesses, you may want high-temp tape rated to 125 °C or even 150 °C.

Real-World Use Cases

-

Example 1: Tesla or other EV manufacturers use flame-retardant harness tape to bundle HV cables.

-

Example 2: OEM suppliers for Ford, GM, Toyota apply wire harness tape inside dashboards or door trims.

-

Example 3: Aftermarket wiring harness makers need hassle-free, durable adhesive tape.

Pro Tips When Ordering

-

Provide sample wiring harness or layout

-

Request sample thermal-aging and peel strength reports

-

Clarify whether you need color-coded rolls (black, orange, etc.)

-

Ask for die-cut harness patches if needed

-

Confirm lead time and freight options

By following these, your next order won’t be a nightmare—it’ll be smooth sailing.

So if you're wondering why automotive wire harness tape matters, the answer’s clear: it’s not a small piece of tape—it’s a reliability component. And choosing the right supplier, especially a China-based factory-direct supplier, means better specs, lower costs, and faster delivery. When done right, it keeps your vehicle systems safe, insulated, and noise-free.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance