Why Is Nylon Cloth Tape Still One of the Most Reliable Options for Wire Bundling?

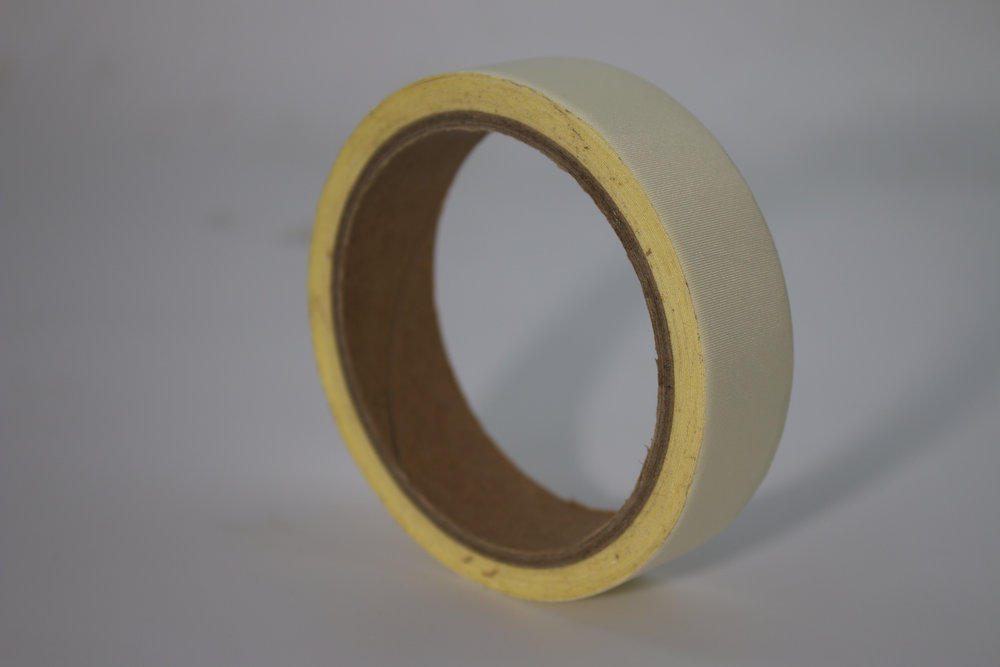

When customers compare different wire-bundling solutions—such as conductive fabric tape, light-blocking tape, and die-cut tape—Nylon Cloth Tape continues to stand out as a classic yet highly dependable choice. Even though newer materials have entered the market, many electricians, automotive technicians, and home-DIY users still prefer nylon for daily wiring tasks. But why does it remain so reliable, especially in environments requiring long-term wire organization and protection?

This article continues the content flow from our previous blogs on EMI shielding tapes and multifunctional adhesive solutions, helping readers better understand how different tapes complement one another in real-world applications.

1. Exceptional Durability Under Daily Mechanical Stress

Unlike many soft tapes that tear easily, Nylon Cloth Tape has a woven structure that provides notable abrasion resistance. For wire harnesses inside vehicles, home appliances, or machinery, wires often rub against metal surfaces, plastic housings, or even other wires.

This is where nylon performs beautifully. The tape forms a tough protective jacket that resists fraying, scratching, and long-term mechanical wear. Some users even say it feels “almost like a fabric shield,” which is kind of true since nylon threads naturally reinforce one another.

And here’s the thing: nylon maintains its strength even after long-term exposure to vibration—something that cheaper tapes simply can't do.

2. Stable Binding Strength that Prevents Wire Loosening

Wire bundling is not only about sticking things together; it’s about ensuring they stay together. Nylon Cloth Tape offers consistent tensile strength, helping wires maintain their shape without slipping apart.

Even after years of use, the tape does not soften or fall off due to heat from devices or engines. Funny enough, some technicians say that “you’ll probably remove the machine before the tape gives up”—a little exaggerated maybe, but not too far from reality.

This steady binding performance also connects well with our previous discussion on die-cut tape, where precision and stability were essential. Similar logic applies here: stable materials make stable wire systems.

3. Excellent Temperature Resistance for Automotive and Home Use

Nylon cloth tape performs well in hot environments such as:

-

automotive engine compartments

-

HVAC equipment

-

household electronic devices

-

lighting fixtures

-

industrial control cabinets

It stays strong even when temperatures rise, unlike vinyl tape that can become gooey or lose adhesion.

Nylon maintains both structure and stickiness, creating a reliable long-term bundle.

Because of this, many automotive wiring harnesses still specify nylon cloth tape as a preferred option.

4. Easy Handling for Faster Installation

Compared to more specialized tapes—such as conductive fabric tape for EMI shielding—nylon cloth tape is refreshingly simple. You can tear it by hand, wrap it quickly, and reposition it before final tightening.

This ease of use is especially helpful for:

-

household repairs

-

DIY electrical projects

-

automotive modifications

-

quick cable cleanup behind desks or entertainment systems

And honestly, everybody loves a material that doesn’t require extra tools. It just makes life a bit easier, right?

5. Noise Reduction and Vibration Dampening

One often-overlooked benefit is its ability to reduce noise. When wires vibrate, they sometimes produce slight rattling sounds against plastic or metal components.

Nylon Cloth Tape naturally cushions these contact points, reducing unwanted noise. This feature is why many car manufacturers still rely on nylon tape for interior wiring bundles—it helps enhance the “silent cabin experience” customers expect.

This closely links to our earlier content on how tapes improve overall electronic performance and system reliability.

6. Strong Compatibility with Other Specialty Tapes

In many wire management systems, nylon cloth tape works alongside:

-

Conductive Fabric Tape for EMI shielding

-

Light-Blocking Tape for optical devices

-

Automotive Wire Harness Tape for engine areas

-

Die-Cut Tape for customized insulation and padding

Its versatility ensures that nylon becomes a base layer or finishing layer in multi-stage wire protection systems.

This inter-product compatibility is an important part of our ongoing content matrix—different tapes serve different roles, but nylon cloth tape often ties them together (literally and functionally).

7. Long-Term Aging Resistance

Sunlight, moisture, and heat often damage traditional tapes over time. Nylon cloth tape, however, resist aging effectively due to its woven synthetic fiber base.

Although no material lasts forever, nylon tape tends to maintain performance longer than many alternatives. Sometimes it even outlast the wire it protects, which shows its reliability.

Nylon Cloth Tape remains one of the most reliable options for wire bundling because of its balance of durability, temperature resistance, noise reduction, ease of handling, and compatibility with other functional tapes. Whether for home electronics, vehicles, industrial machines, or daily cable organization, it continues to be a practical and long-lasting choice.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance