Why Light-Blocking Tape Matters More Than You Think in Modern Electronics

When people think about the tapes used in electronics, they often picture conductive tapes for EMI protection or cloth tapes for cable wrapping. But there’s one unsung hero quietly shaping the visual quality of every screen, display, and camera — Light-Blocking Tape.

It may look simple at first glance, but in modern devices where every millimeter counts, this tape plays a crucial role. Without it, your smartphone display might bleed light, your car’s sensor panel might misread data, and your home projector might lose contrast. Let’s dig into why it’s so essential.

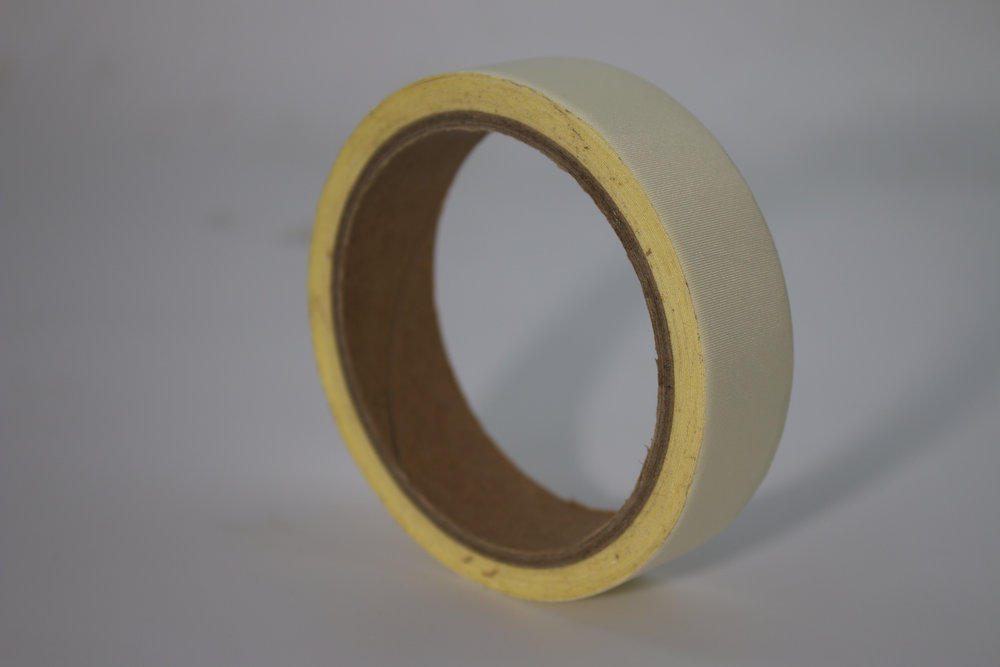

1. What Is Light-Blocking Tape?

Light-Blocking Tape, sometimes called black-out tape, is a specialized adhesive tape designed to prevent light transmission. It typically consists of PET, non-woven fabric, or matte-coated materials, combined with high-opacity black adhesive.

In simple terms, it absorbs or blocks unwanted light — whether it’s from LED backlights, optical sensors, or display edges.

The key features include:

-

High opacity (>99%) for total light shielding

-

Matte, anti-reflection surface to minimize glare

-

Heat resistance and dimensional stability

-

Strong adhesive that doesn’t seep under heat

-

Precision die-cut compatibility

And just like our Die-Cut Tape Series, it can be customized into complex shapes to match lenses, modules, and housings perfectly.

2. Where Do You Actually Need Light-Blocking Tape?

You’d be surprised how often this tape shows up in daily life — you just never notice it. Here are some major applications:

-

Display modules – Blocks side-light leakage around LCD or OLED edges.

-

Camera lenses & sensors – Ensures accurate light capture and color balance.

-

Touch panels – Enhances contrast by eliminating background light interference.

-

Automotive interiors – Used in dashboards, ambient lighting systems, and HUDs.

-

Smart home devices – Prevents LED indicator lights from causing glare.

-

Medical imaging equipment – Keeps optical paths clean and accurate.

So yeah, it’s basically working behind the scenes to make sure what you see looks perfect.

3. How It Works Together with Other Yijiayi Tapes

This is where our product ecosystem shines.

In many electronics assemblies, Light-Blocking Tape is layered with other tapes for combined performance.

For instance:

-

Combine it with Conductive Fabric Tape for light + EMI shielding in camera modules.

-

Use it with Nylon Cloth Tape to strengthen adhesion and mechanical protection in high-heat areas.

-

Pair it with Die-Cut Tape for precision bonding and shape-fit sealing.

At Anhui Yijiayi Technology Co., Ltd., we produce all of these tapes under one roof — so clients can customize multi-layer composite solutions that meet both optical and electrical requirements.

This level of integration ensures consistency and reliability, something that’s hard to find when sourcing from multiple suppliers.

4. The Role of Customization in Light-Blocking Tape

One size never fits all, especially in optical engineering.

That’s why we provide full customization options, including:

-

Thickness: 0.03mm to 0.25mm

-

Base material: PET, non-woven fabric, black paper

-

Surface type: Glossy or matte finish

-

Adhesive type: Heat-resistant, removable, or high-tack acrylic

-

Shape processing: Die-cutting or kiss-cutting for specific assemblies

Our precision die-cut process (±0.1mm tolerance) ensures every piece fits perfectly — something we already discussed in our previous Die-Cut Tape article.

5. Why Engineers and Designers Prefer Our Light-Blocking Tape

Because details matter.

When engineers design devices with backlighting or optical components, even the smallest light leakage can ruin performance or aesthetics.

Our Light-Blocking Tape helps them solve issues like:

-

Uneven light distribution in displays

-

Reflection inside camera modules

-

Leakage around LED panels or covers

-

Edge-glow in touchscreens

It’s also easy to apply, with stable adhesion even after long heat exposure — meaning fewer reworks and higher productivity.

And honestly, that’s what most of our industrial clients love — it just works.

6. A Greener Future: Eco-Friendly Blackout Solutions

As with all Yijiayi products, sustainability is built into the process.

Our light-blocking tapes are ROHS-compliant, halogen-free, and made with low-VOC adhesives.

We’re actively researching biodegradable PET bases and water-based adhesives that deliver the same performance while reducing environmental impact.

So, when you choose Yijiayi, you’re not just getting precision — you’re getting responsibility.

From smartphones to EV dashboards, Light-Blocking Tape has quietly become a cornerstone of modern design. It ensures clarity, precision, and reliability — everything customers expect but rarely think about.

And that’s what we specialize in — the details that make everything else shine.

If you’ve already read our previous posts on Nylon Cloth Tape or Conductive Fabric Tape, you’ll notice the same philosophy:

different functions, one goal — better performance through smarter adhesive solutions.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance