How Can Printable and Light-Blocking Tapes Enhance Industrial and Electronic Applications?

When it comes to industrial efficiency, precision electronics, or even office organization, many companies overlook the impact of specialty tapes. But have you ever wondered how printable tapes and light-blocking tapes can improve productivity, accuracy, and product quality? Let’s dive in.

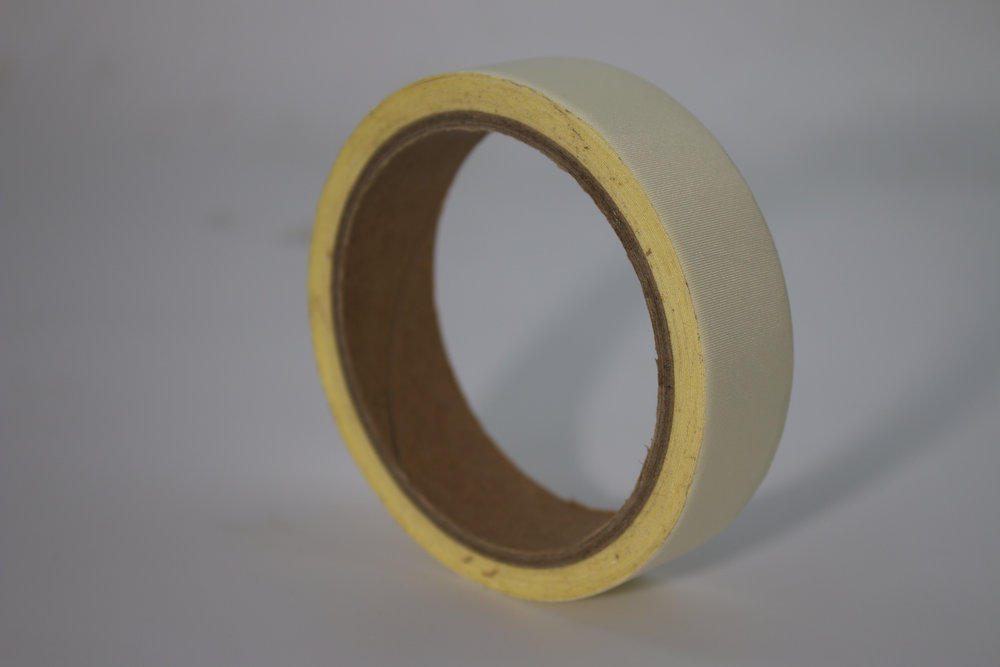

The Versatility of Printable Tapes

Printable tapes are no longer just for labeling. They are essential tools in logistics, manufacturing, and electronics. Some common applications include:

-

Warehouse and storage labeling: Durable tapes that withstand abrasion, moisture, and UV exposure.

-

Electronic component labeling: High-resolution printing ensures traceability in PCBs, sensors, and wiring harnesses.

-

Custom packaging: Promotional branding with logos or QR codes directly printed on tape.

-

Office and educational use: Color-coded indexing and labeling for easy organization.

By choosing customizable printable tapes from China-based suppliers, companies can adapt to specific sizes, materials, and adhesive strengths, making workflows more efficient and professional.

Why Light-Blocking Tapes Matter

Light-blocking tapes are designed to prevent unwanted light leakage in sensitive applications. They are widely used in:

-

Displays and monitors: Blocking edge light or reflections to improve screen clarity.

-

Cameras and optical devices: Preventing infrared interference and controlling light paths.

-

VR and AR equipment: Ensuring immersive experiences without light leak distractions.

-

Industrial electronics: Covering panels or sensors to maintain calibration and accuracy.

Some tapes also offer high temperature resistance, matte finishes, and removable adhesives, which makes them perfect for both production and maintenance.

Combining Printable and Light-Blocking Tapes

In many production or repair scenarios, using both types together adds value:

-

Traceable and protected components: Printable tapes provide clear identification, while light-blocking tapes shield sensitive components from ambient light.

-

Custom workflows: Factory-direct suppliers in China can provide OEM customization, letting you choose thickness, color, width, adhesive, and even pre-cut shapes.

-

Enhanced productivity: Quick identification and reliable shielding reduce errors and maintenance time.

Benefits of Sourcing Directly from Manufacturers

Working directly with a China-based manufacturer and supplier ensures you get:

-

Factory-direct pricing: Reduce costs without compromising quality

-

Custom solutions: Printable tapes in PET, cloth, or synthetic materials; light-blocking tapes with matte or glossy finishes

-

Bulk and OEM orders: Suitable for industrial production, electronics assembly, or retail packaging

-

Wide product variety: Printable tapes, light-blocking tapes, conductive tapes, die-cut tapes, and acetate cloth tapes

By sourcing directly, companies get the best value, reliability, and customization options for their industrial and electronic needs.

Printable and light-blocking tapes are more than simple adhesives—they are productivity enhancers, quality protectors, and workflow optimizers. Whether for industrial machines, electronics assembly, or office applications, these tapes ensure accuracy, protection, and efficiency.

Partnering with a trusted China-based manufacturer like Anhui Yijiayi Technology Co., Ltd. guarantees high-quality, customizable, and factory-direct solutions that meet diverse industrial and commercial requirements.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance