How Light-Blocking Tape Enhances Product Performance in Modern Devices?

When you think about everyday devices like smartphones, TVs, or even car dashboards, you probably don’t notice the small details that make them function so perfectly. One of those hidden heroes is Light-Blocking Tape — a simple yet essential component that ensures clarity, contrast, and precision in modern electronics.

In our previous blogs, we talked about the importance of Conductive Fabric Tape for EMI protection and Automotive Wire Harness Tape for secure electrical connections. Today, we’ll explore how Light-Blocking Tape complements those solutions and why it plays such a vital role in design, performance, and user experience.

1. What Is Light-Blocking Tape?

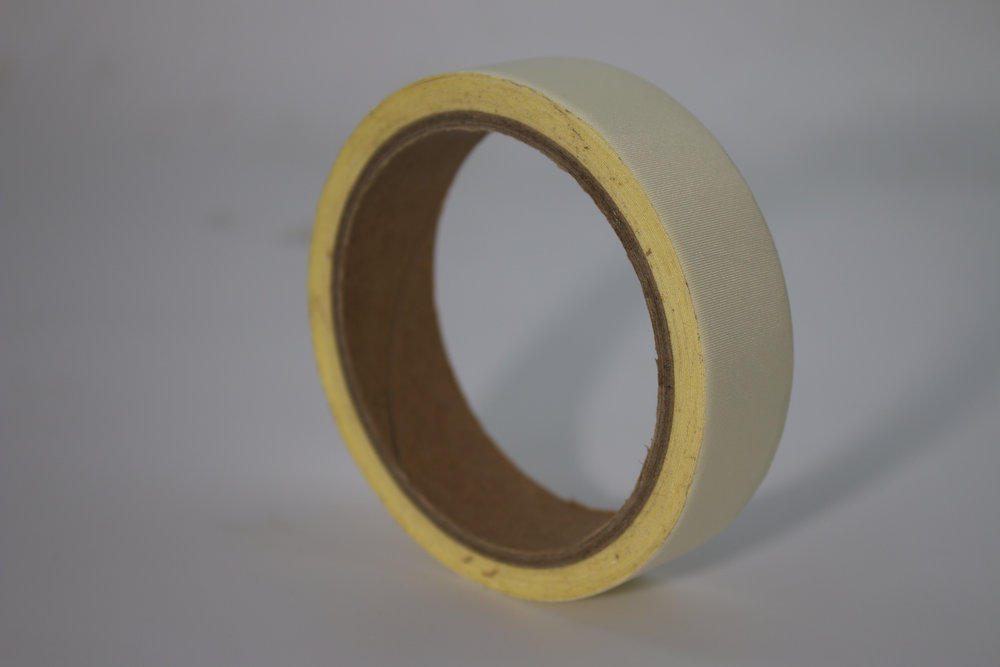

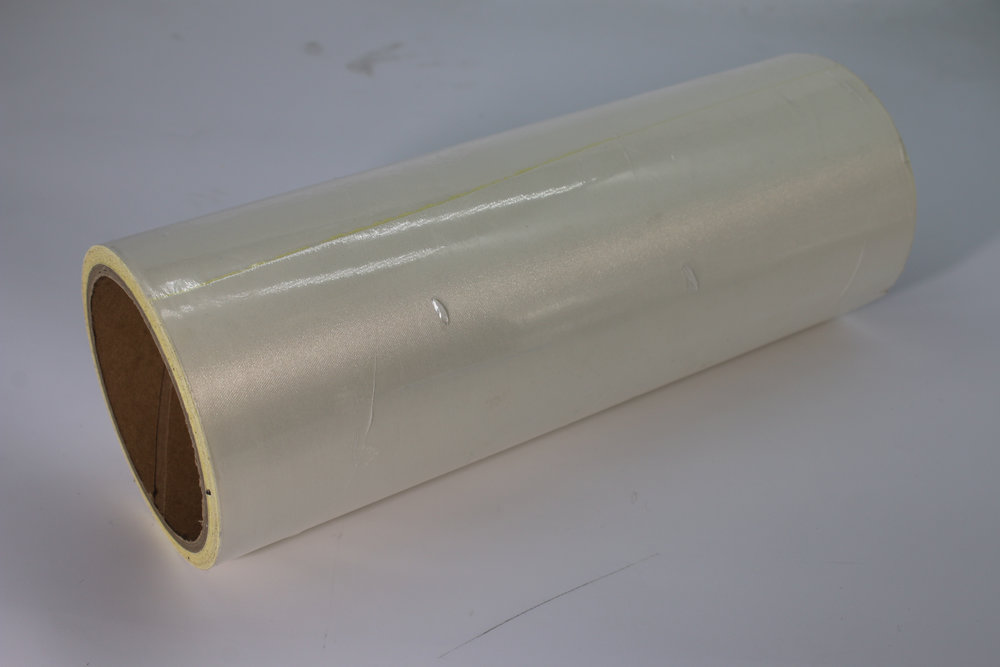

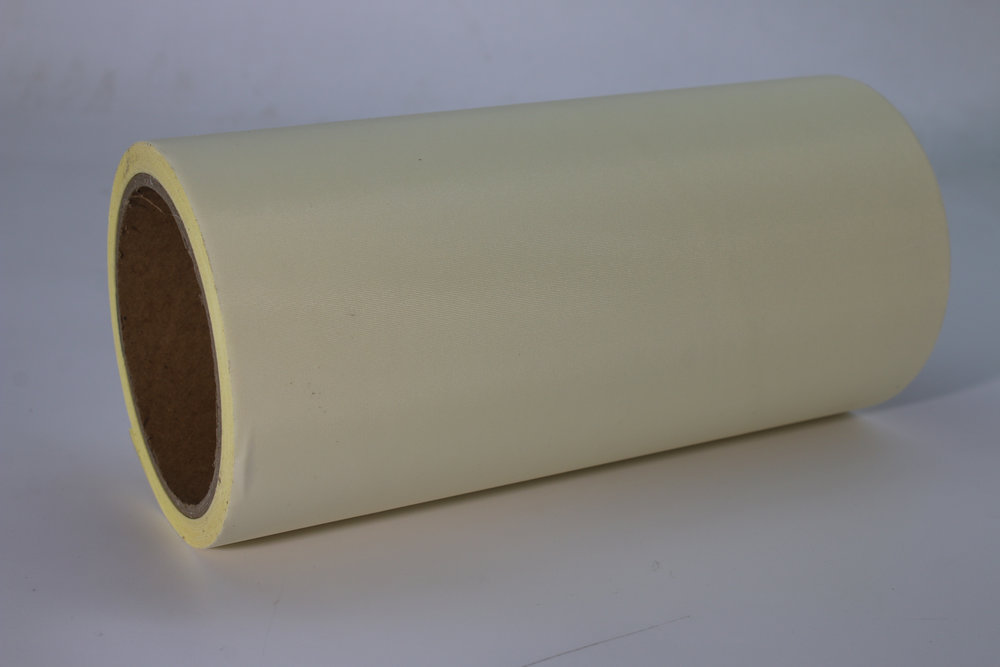

Light-Blocking Tape is a specialized adhesive tape designed to prevent light leakage from display panels, LED modules, and other illuminated parts. It ensures that the light stays exactly where it’s needed — no more, no less.

Typically made with black PET or non-woven materials and coated with high-performance adhesives, this tape can block both visible and infrared light. For products requiring aesthetic consistency, it can also serve as a decorative masking material, creating neat edges and clean finishes.

2. Why Light Leakage Is a Serious Problem

Imagine watching a high-end TV in a dark room — and you see light bleeding around the screen edges. It breaks the immersion instantly, right? That’s exactly what light-blocking tape prevents.

In smartphones, smartwatches, and automotive displays, even tiny light leaks can affect visual quality and brand perception. For manufacturers, that’s not just a design flaw — it’s a quality control issue. By applying high-density Light-Blocking Tape, brands can maintain consistent optical performance across devices.

3. Applications Across Multiple Industries

You might be surprised, but this tape is used in more places than you think!

-

Consumer Electronics: Smartphones, tablets, TVs, and VR headsets.

-

Automotive Displays: Dashboards, head-up displays, control panels.

-

Home Appliances: Air conditioners, refrigerators, and microwave panels.

-

Optical Equipment: Cameras, scanners, and projectors.

And here’s the cool part — when used together with Conductive Fabric Tape and Printable Tape, manufacturers achieve both light management and electromagnetic shielding, resulting in cleaner, more efficient products.

4. Key Benefits You Shouldn’t Ignore

Light-Blocking Tape isn’t just about aesthetics — it directly affects functionality.

-

Improved display contrast

-

Reduced light interference in optical sensors

-

Enhanced durability under heat or humidity

-

Better product appearance and precision assembly

Plus, with custom die-cutting (like our Die-Cut Tape Series), every piece fits perfectly into intricate design spaces, saving assembly time and cost.

5. Why Choose Yijiayi Light-Blocking Tape

At Anhui Yijiayi Technology Co., Ltd., we specialize in developing eco-friendly and high-performance tapes tailored to modern manufacturing demands. Our Light-Blocking Tape Series offers strong adhesion, stable performance, and customizable dimensions — perfect for industries seeking precision and reliability.

We also produce Conductive Fabric Tape, Automotive Wire Harness Tape, Acetate Cloth Tape, and more — creating a full lineup that supports every stage of your product’s design and assembly.

So, whether you’re building a next-generation display or optimizing your current model, we’ve got you covered.

6. A Quick Wrap-Up

Light-Blocking Tape may not grab attention like a shiny new gadget, but it’s the unsung hero behind every flawless display and seamless visual experience. In combination with other functional tapes, it ensures that devices perform exactly as intended — bright where it should be, dark where it must be.

By choosing reliable solutions from Yijiayi, you don’t just improve one component — you elevate your entire product line.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance