Light-Blocking Tape: Why It Matters in Modern Display and Lighting Design

In our previous article, we explored how Printable Tape enhances design flexibility and labeling efficiency. But when it comes to display technology, precision goes far beyond clear labeling — it’s about light control. That’s where Light-Blocking Tape comes in — a product quietly shaping how we experience screens, lighting, and visual clarity in everyday life.

So, what exactly does this tape do, and why is it becoming a go-to solution in industries like electronics, display manufacturing, and automotive lighting? Let’s dive deeper.

1. What Is Light-Blocking Tape?

Light-blocking tape, also known as blackout tape, is a high-performance adhesive material designed to block, absorb, or reflect unwanted light. It’s used in devices where even the smallest light leakage can impact performance or appearance — think LED panels, LCD displays, cameras, and even car dashboards.

This tape typically comes in several variations:

-

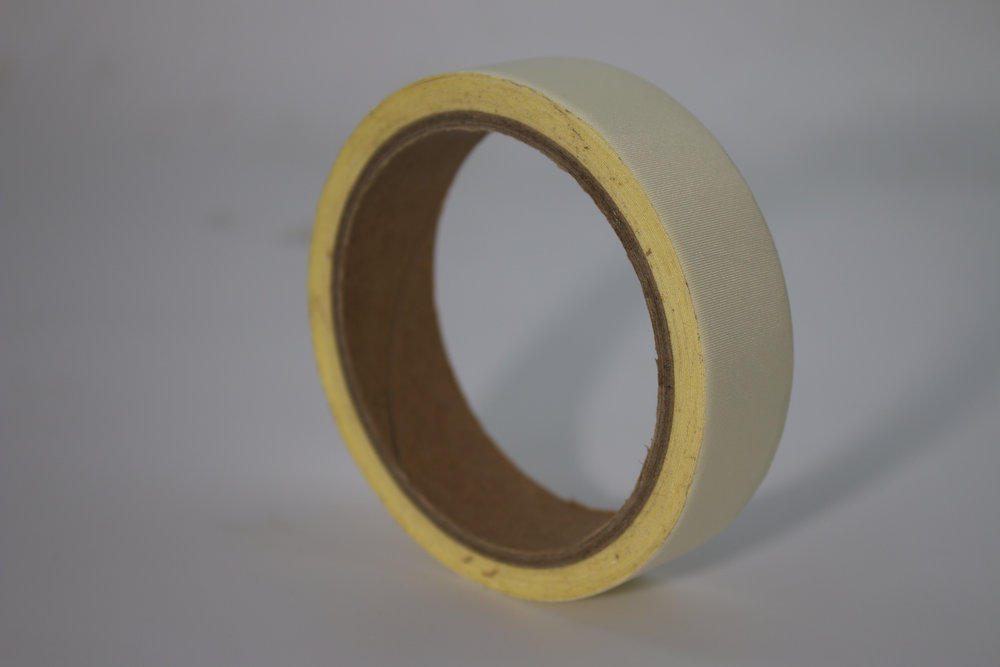

PET Light-blocking Tape (polyester-based, smooth, durable)

-

Fabric-based Light-blocking Tape (flexible, tear-resistant)

-

Aluminum-layered Light-blocking Tape (high reflection control)

-

Non-woven Light-blocking Tape (lightweight, easy to process)

Each serves a specific function depending on whether your goal is to absorb stray light, enhance contrast, or protect sensitive optical components.

2. Why Is Light Control So Important in Displays?

Imagine watching your phone screen under sunlight, or an automotive display at night — too much light leakage and you lose contrast; too little and you lose visibility. Light-blocking tape ensures balance and precision.

By sealing gaps, borders, and edges inside screens, it prevents internal light from leaking, resulting in a sharper, more defined display. This is especially critical in OLED and mini-LED devices where optical clarity defines product quality.

And guess what? It’s not only about looks. Proper light management also reduces power waste and extends the lifespan of light-emitting components. That’s real efficiency.

3. The Connection Between Light-Blocking and Printable Tapes

If you read our last blog about Printable Tape, you might’ve noticed how both products emphasize precision and customization.

While printable tapes bring clarity in communication (labeling, design, identification), light-blocking tapes bring clarity in visual performance. Both are essential in electronic manufacturing — especially in sectors like smartphones, tablets, and automotive control panels.

Together, they form a dual-function solution:

-

Printable Tape labels components or wiring accurately.

-

Light-blocking Tape maintains display brightness and contrast.

This synergy is a good reminder of how our Yijiayi Tape Series works as a complete system rather than individual products.

4. Functional Benefits Across Industries

Light-blocking tape’s versatility makes it indispensable across multiple industries:

-

Electronics: Used in displays, sensors, and cameras for light shielding

-

Automotive: Applied to dashboards, headlight assemblies, and interior LEDs

-

Home Appliances: Keeps light diffusion consistent in refrigerators or control panels

-

Optics & Imaging: Prevents glare in lenses and optical modules

-

Medical Devices: Helps maintain accuracy in diagnostic screens or sensors

Moreover, some models — like our removable or high-temperature-resistant light-blocking tapes — are designed to perform under extreme conditions such as LED assembly lines and soldering processes.

5. Yijiayi’s Commitment to Quality and Customization

At Anhui Yijiayi Technology Co., Ltd., we take pride in offering customizable light-blocking tape solutions.

Our products are available in various materials, thicknesses, widths, and adhesive types, supporting different industrial requirements.

We also offer:

-

Removable options (no residue)

-

High-temperature and flame-retardant grades

-

Color and logo customization

-

Die-cut shapes for precise application

Our mission is simple — to provide the best performance with the least waste, combining sustainability with high-end functionality.

6. Future Trends: Smarter Displays Need Smarter Materials

As display technology advances — think AR/VR headsets, transparent OLEDs, and smart dashboards — light control becomes even more crucial. Manufacturers now look for light-blocking materials that are thinner, lighter, and more durable.

Yijiayi is investing in composite structures, such as double-layer blackout tapes and carbon-loaded absorptive coatings, to meet these next-generation needs.

You see, while printable and conductive tapes focus on visibility and electrical control, light-blocking tapes ensure visual perfection.

Each complements the other — that’s what makes our product lineup a complete ecosystem.

From conductive cloth tape ensuring EMI protection, to printable tape enabling design precision, and now light-blocking tape managing illumination — Yijiayi continues to innovate across every layer of industrial tape technology.

Our customers, whether in electronics, automotive, or lighting, trust us for consistent quality, customization, and long-term reliability.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance