What Is Conductive Fabric Tape Used For? Full Guide for Industrial Buyers

In today’s electronics-driven world, Conductive Fabric Tape has become a go-to solution for EMI shielding, grounding, and anti-static applications. Whether you're a purchasing manager in the automotive sector or a supplier in electronics manufacturing, knowing when and how to use conductive fabric tape can save you money, time, and lots of headaches.

In this guide, we’ll explain the most common applications, features, and sourcing tips for conductive fabric tapes. Let’s dive right in!

What Is Conductive Fabric Tape?

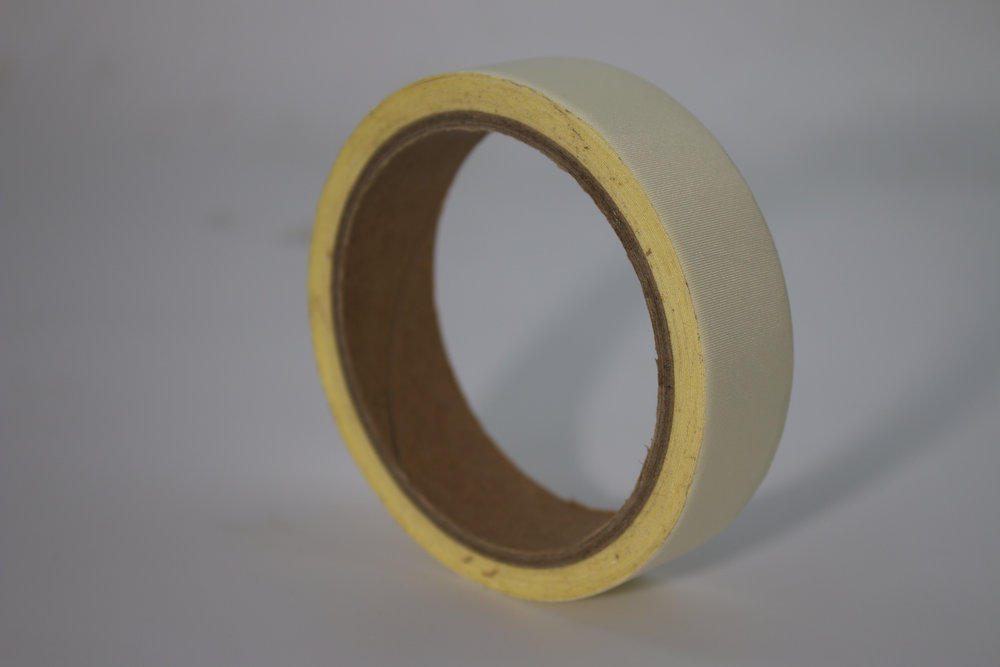

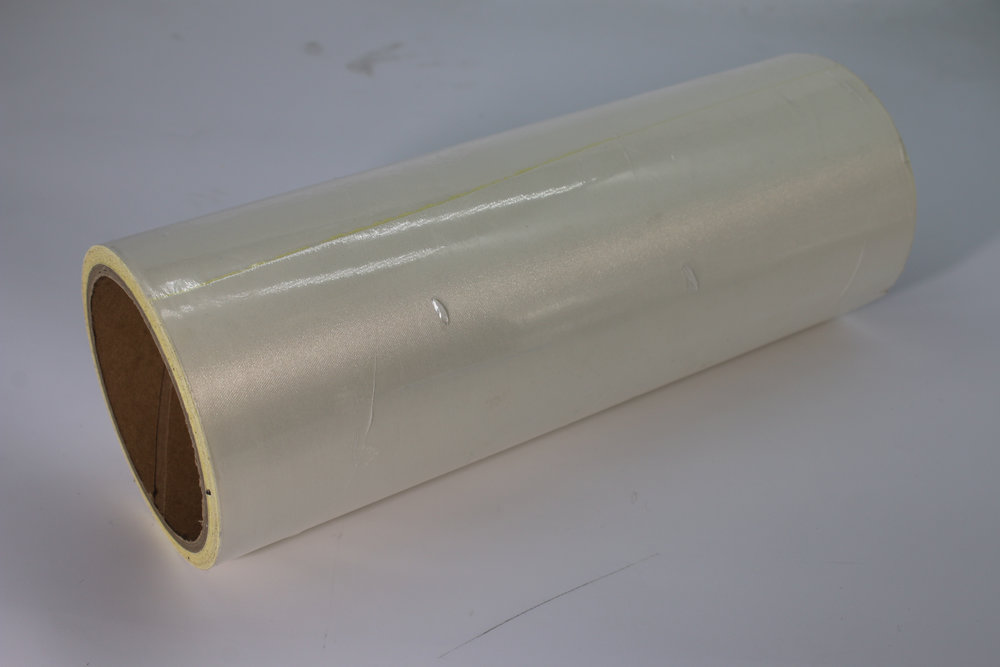

Conductive fabric tape is a type of pressure-sensitive adhesive tape made from metalized woven or non-woven fabric, usually coated with conductive adhesive. It's widely used for electromagnetic interference (EMI) shielding, electrostatic discharge (ESD) protection, and signal grounding.

This tape works by forming a continuous conductive path over a surface or around a cable or component. It is flexible, often solderable, and available in custom die-cut shapes or rolls.

Main Applications Across Industries

1. Consumer Electronics

EMI shielding in smartphones, laptops, tablets, and smartwatches is one of the top applications. Many manufacturers apply die-cut conductive tapes inside the device housing or under the battery compartment.

2. Automotive & EVs

With electric vehicles (EVs) becoming mainstream, EMI shielding inside control units, battery modules, and infotainment systems is critical. Conductive fabric tape offers a lightweight, flexible alternative to traditional foil shields.

3. Medical Equipment

Hospitals need machines to work accurately. Conductive tapes help reduce EMI in imaging devices, monitors, and diagnostic equipment. Oh, and they’re often biocompatible too (but double-check that when sourcing).

4. Industrial Automation & Robotics

Cables and connectors in robotic arms are often wrapped with conductive fabric tape for anti-static performance. It also protects signals in noisy environments like motor control systems or wireless modules.

5. Aerospace & Defense

Shielding avionics, antennas, or communication cables is mission-critical. Tapes that meet military-grade specs are chosen for performance under high vibration and extreme temperatures.

Key Features You Should Look For

-

High EMI shielding effectiveness (40–80 dB depending on frequency)

-

Low surface resistance (ideally <0.05 ohms/sq)

-

Flexible and conformable backing – usually polyester or nylon base

-

Conductive adhesive – acrylic or silicone-based

-

UL94 V-0 flame rating for high-safety applications

-

Available in custom widths, die-cuts, and shapes

If your current supplier can’t meet one of these — maybe it’s time to change!

Why Work with a China-Based Manufacturer?

Here's the thing: not all tapes are created equal. When you’re buying in volume or need custom conductive fabric tape, choosing a China-based manufacturer or B2B supplier gives you more flexibility, better pricing, and quicker prototyping.

Chinese factories often support:

-

OEM/ODM projects

-

Custom widths, thicknesses, and adhesive types

-

Die-cut processing based on CAD or AI files

-

Shorter lead times for batch orders

-

Cost-effective shipping solutions to the US

P.S. Don’t forget to ask for RoHS and REACH certification.

Common Questions from Buyers (FAQ Style)

Q1: Can conductive fabric tape replace aluminum foil tape?

Yes, in many cases. Especially where flexibility and fabric conformability are needed.

Q2: Can it be used outdoors?

It depends on the adhesive and backing. Some tapes offer UV resistance and waterproofing.

Q3: Is it printable or brandable?

Yes, some conductive tapes can be laser-marked or labeled during manufacturing.

Q4: What’s the MOQ for custom die-cut orders?

If you work with a Chinese conductive fabric tape supplier, the MOQ can be as low as 3,000 pieces or one full roll.

Final Thoughts

Conductive fabric tape is more than just a component — it’s a strategic solution in modern product design and EMI protection. If you’re sourcing from overseas, partnering with a conductive fabric tape manufacturer in China could streamline your supply chain and give you access to custom specs at competitive prices.

Choosing the right supplier can be tricky, but once you do, your operations will run smoother. Just saying – it’s worth the effort.

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

From Vietnam to Europe: Anhui Yijiayi Technology's Exhibition Journey in Industrial Adhesive Tapes

5 Common Tape Installation Errors That Cause Electrical Failures

5 Common Tape Installation Errors That Cause Electrical Failures

How to Layer Conductive and Insulating Tapes for Maximum Safety

How to Layer Conductive and Insulating Tapes for Maximum Safety

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Choosing the Right Adhesive for Heat-Resistant Electrical Tapes

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Tape vs Insulating Tape: When Do You Need Both?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Conductive Cloth Tape vs Aluminum Foil Tape: Which Handles Heat Better?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Heat Resistance Matters When Choosing Tape for Electrical Equipment?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Why Is Acetate Cloth Tape Widely Used in Transformers and Motors?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Acetate Cloth Tape vs Nylon Cloth Tape: Which One Fits Your Application Better?

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance

Printable Tape: How Custom Labels Improve Wiring Identification and Maintenance